Table of Contents

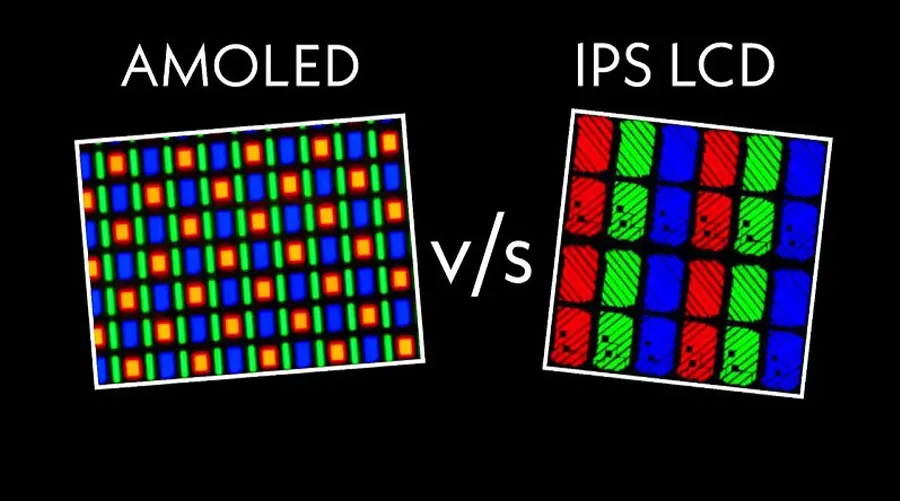

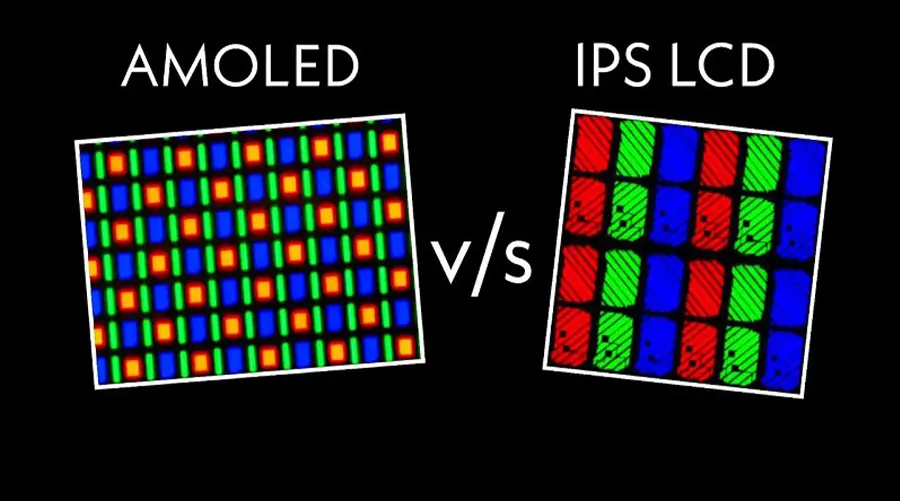

1. Introduction to TFT and OLED

Thin-Film Transistor (TFT) and Organic Light-Emitting Diode (OLED) technologies are the cornerstones of modern display innovation. TFT-LCDs dominate the market for large-format screens like TVs and monitors, while OLEDs lead in high-end smartphones, wearables, and flexible displays. This article explores the science, manufacturing, and real-world applications of these technologies, leveraging insights from leading Chinese manufacturers such as BOE, CSOT, and Visionox.

Key Differences at a Glance

| Feature | TFT-LCD | OLED |

|---|---|---|

| Backlight Required | Yes (LED/CCFL) | No (self-emissive) |

| Contrast Ratio | ~500:1 | Up to 1,000,000:1 |

| Flexibility | Rigid panels | Flexible/foldable designs |

| Power Efficiency | Moderate | High for dark content |

| Cost | $15–$30/cm² | $30–$50/cm² |

2. TFT Technology: Principles and Applications

What is TFT?

TFT (Thin-Film Transistor) is a semiconductor technology used in LCDs (Liquid Crystal Displays) to control individual pixels. TFT-LCDs combine a liquid crystal layer with a backlight and a TFT array to produce high-resolution images.

Key Components of TFT-LCDs

-

Glass Substrates: Typically 700–1200mm in size, made of soda-lime or alkali-free glass.

-

Thin-Film Deposition: Layers of silicon dioxide (SiO₂), silicon nitride (SiN), and indium tin oxide (ITO) are deposited via chemical vapor deposition (CVD).

-

Photolithography: A multi-step process using 4–6 masks to pattern the TFT array.

-

Cell Assembly: Liquid crystals are sealed between two substrates with spacers to maintain uniform thickness.

Applications of TFT-LCDs

-

Television and Monitor Manufacturing: Dominates the TV market due to cost-effectiveness.

-

Industrial Automation: Used in medical devices (e.g., diagnostic equipment) and industrial control panels.

-

Automotive Displays: Integrated into car dashboards and infotainment systems.

Case Study: BOE's B7 Line

BOE’s B7 line in Chengdu produces 48K/M AMOLED panels using LTPS (Low-Temperature Polycrystalline Silicon) technology. This line achieves 1000 cd/m² brightness and supports 120Hz refresh rates, making it ideal for high-end smartphones.

3. OLED Technology: Advantages and Challenges

What is OLED?

OLED (Organic Light-Emitting Diode) uses organic compounds that emit light when electrically stimulated. Unlike TFT-LCDs, OLEDs do not require a backlight, enabling ultra-thin, flexible displays with perfect blacks and wide viewing angles.

Advantages of OLED

-

High Contrast Ratio: Achieves 1,000,000:1 due to self-emissive pixels.

-

Flexibility: Enables foldable phones (e.g., Huawei Mate X3) and curved TVs.

-

Energy Efficiency: Consumes less power for dark scenes compared to TFT-LCDs.

Challenges in OLED Manufacturing

-

Blue OLED Lifespan: Blue organic materials degrade faster than red/green, requiring advanced phosphorescent emitters.

-

Production Costs: Vacuum deposition processes are expensive, with costs reaching $30–$50/cm².

-

Yield Rates: Lower than TFT-LCDs (typically 60–70% due to material defects).

Case Study: Visionox's V2 Line

Visionox’s V2 line in Guangzhou focuses on AMOLED production with Cu (Copper) and LTPO (Low-Temperature Polycrystalline Oxide) technologies. This line supports FDA-certified medical devices and automotive displays, achieving 30K/M capacity by 2023.

4. Manufacturing Processes of TFT and OLED

TFT-LCD Manufacturing Steps

-

Glass Substrate Preparation: Cleaning and chemical strengthening.

-

Thin-Film Deposition: Layers of SiO₂, SiN, and ITO.

-

Photolithography: 4–6 masks to define pixel arrays.

-

Cell Assembly: Liquid crystal injection and sealing.

-

Backlight Integration: LED or CCFL backlights added for illumination.

OLED Manufacturing Steps

-

Substrate Selection: Glass or polymer films for flexibility.

-

Vacuum Deposition: Organic materials (e.g., TADF emitters) deposited via inkjet printing or thermal evaporation.

-

Encapsulation: Sealing with thin-film barriers to prevent moisture ingress.

-

Driver IC Integration: TFT arrays control pixel brightness and color.

Comparative Metrics

| Parameter | TFT-LCD | OLED |

|---|---|---|

| Brightness | 300–800 cd/m² | 500–1000 cd/m² |

| Response Time | 5–8 ms | 0.1 ms |

| Power Consumption | 3–5 W (10-inch screen) | 2–4 W (10-inch screen) |

| Yield Rate | ~75% | ~60% |

5. Leading Factories and Case Studies

BOE's B1 Line (Beijing)

Project: Mini LED integration for LCD backlights.

Outcome: Achieved 100K/M TFT-LCD capacity with 9K/M Mini LED conversion, boosting backlight efficiency by 30%.

CSOT's T4 Line (Wuhan)

Focus: AMOLED production for automotive displays.

Capacity: 48K/M with 1000 cd/m² brightness.

Technology: Uses Cu-based TFT circuits for improved conductivity.

Visionox's V3 Line (Chengdu)

Innovation: Printed OLED using inkjet technology.

Cost Reduction: Cuts material waste by 40%, targeting mass-market adoption.

6. TFT vs OLED: A Detailed Comparison

Performance Metrics

| Feature | TFT-LCD | OLED |

|---|---|---|

| Color Accuracy | Slightly lower (8-bit) | Superior (10-bit) |

| Viewing Angle | 120–140° | 170°+ |

| Refresh Rate | 60–120Hz | 60–120Hz |

| Durability | Longer lifespan | Susceptible to burn-in |

Market Share (2023)

TFT-LCD: 65% of global display shipments (used in TVs, monitors).

OLED: 35% of shipments, concentrated in smartphones and wearables.

7. Future Trends and Innovations

MicroLED Displays

BOE’s B1 Line: Produces Mini LED backlights for LCDs, achieving 20,000m² annual output.

Samsung’s QD-OLED: Combines quantum dots with OLED for enhanced brightness.

LTPO for AMOLED

CSOT’s T6 Line: Implements LTPO (Low-Temperature Polycrystalline Oxide) for 120Hz refresh rates and dynamic frame rate adjustments.

Printed OLED

Visionox’s Vistar Line: Experiments with inkjet printing to reduce costs and scale production.

8. FAQs About TFT and OLED

Q1: What is the difference between a-Si and LTPS TFTs?

a-Si (Amorphous Silicon): Cost-effective for large panels (e.g., TVs).

LTPS (Low-Temperature Polycrystalline Silicon): Higher electron mobility for small, high-resolution displays (e.g., smartphones).

Q2: Why are OLEDs more expensive than TFT-LCDs?

Vacuum Deposition: Complex and costly process for organic materials.

Material Costs: Phosphorescent emitters and encapsulation materials increase expenses.

Q3: How do Cu processes improve OLED performance?

Copper (Cu) replaces aluminum (Al) in TFT circuits, enhancing conductivity and stability for high-refresh-rate displays.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Recommended products

-

7.0 inch IPS High brightness TFT without Touchscreen

BR070JII 2757-B4 V.1 IntroductionThis exceptional 7.0-inch TFT LCD module powered by an a-Si TFT act

-

10.1 inch IPS LVDS Interface TFT without Touchscreen

BR101DHI3625-A4 V.1 IntroductionSure. BR101DHI3625-A4 V.1 is an advanced TFT LCD Module that stands

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Product Specifications: BRO392001AResolution: 1080x1024Operating Voltage Range: 28VScreen Size: 3.92

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Product Specifications: BRO548001AResolution: 1080x1920Operating Voltage Range: 2.8VScreen Size: 5.4