Змест

1. Introduction to TFT and OLED

Thin-Film Transistor (TFT) and Organic Light-Emitting Diode (OLED) technologies are the cornerstones of modern display innovation. TFT-LCDs dominate the market for large-format screens like TVs and monitors, while OLEDs lead in high-end smartphones, wearables, and flexible displays. This article explores the science, manufacturing, and real-world applications of these technologies, leveraging insights from leading Chinese manufacturers such as BOE, CSOT, and Visionox.

Key Differences at a Glance

| Асаблівасць | TFT-LCD | ТЫ ЁСЦЬ |

|---|---|---|

| Backlight Required | Yes (LED/CCFL) | No (self-emissive) |

| Каэфіцыент кантраснасці | ~500:1 | Up to 1,000,000:1 |

| Гнуткасць | Rigid panels | Flexible/foldable designs |

| Энергаэфектыўнасць | Умераны | High for dark content |

| Кошт | $15–$30/cm² | $30–$50/cm² |

2. TFT Technology: Principles and Applications

What is TFT?

TFT (Thin-Film Transistor) is a semiconductor technology used in LCDs (Liquid Crystal Displays) to control individual pixels. TFT-LCDs combine a liquid crystal layer with a backlight and a TFT array to produce high-resolution images.

Key Components of TFT-LCDs

-

Glass Substrates: Typically 700–1200mm in size, made of soda-lime or alkali-free glass.

-

Thin-Film Deposition: Layers of silicon dioxide (SiO₂), silicon nitride (SiN), and indium tin oxide (ITO) are deposited via chemical vapor deposition (CVD).

-

Photolithography: A multi-step process using 4–6 masks to pattern the TFT array.

-

Cell Assembly: Liquid crystals are sealed between two substrates with spacers to maintain uniform thickness.

Applications of TFT-LCDs

-

Television and Monitor Manufacturing: Dominates the TV market due to cost-effectiveness.

-

Industrial Automation: Used in medical devices (e.g., diagnostic equipment) and industrial control panels.

-

Аўтамабільныя дысплеі: Integrated into car dashboards and infotainment systems.

Case Study: BOE's B7 Line

BOE’s B7 line in Chengdu produces 48K/M AMOLED panels using LTPS (Low-Temperature Polycrystalline Silicon) technology. This line achieves 1000 cd/m² brightness and supports 120Hz refresh rates, making it ideal for high-end smartphones.

3. OLED Technology: Advantages and Challenges

What is OLED?

OLED (Organic Light-Emitting Diode) uses organic compounds that emit light when electrically stimulated. Unlike TFT-LCDs, OLEDs do not require a backlight, enabling ultra-thin, flexible displays with perfect blacks and wide viewing angles.

Перавагі OLED-дысплеяў

-

Высокі каэфіцыент кантраснасці: Achieves 1,000,000:1 due to self-emissive pixels.

-

Flexibility: Enables foldable phones (e.g., Huawei Mate X3) and curved TVs.

-

Энергаэфектыўнасць: Consumes less power for dark scenes compared to TFT-LCDs.

Challenges in OLED Manufacturing

-

Тэрмін службы сіняга OLED-дысплея:Сінія арганічныя матэрыялы раскладаюцца хутчэй, чым чырвоныя/зялёныя, і патрабуюць перадавых фасфарэсцэнтных выпраменьвальнікаў.

-

Выдаткі на вытворчасць:Працэсы вакуумнага нанясення з'яўляюцца дарагімі, іх кошт дасягае 30–50 долараў/см².

-

Паказчыкі прыбытковасці:Ніжэй, чым у TFT-LCD (звычайна 60–70% з-за дэфектаў матэрыялу).

Тэматычнае даследаванне: лінейка V2 ад Visionox

Лінія V2 кампаніі Visionox у Гуанчжоу сканцэнтравана на вытворчасці AMOLED-дысплеяў з выкарыстаннем тэхналогій Cu (медзі) і LTPO (нізкатэмпературнага полікрышталічнага аксіду). Гэтая лінія падтрымлівае сертыфікаваныя FDA медыцынскія прылады і аўтамабільныя дысплеі, дасягнуўшы магутнасці 30 тыс./млн да 2023 года.

4. Manufacturing Processes of TFT and OLED

Этапы вырабу TFT-LCD

-

Падрыхтоўка шкляной падкладкі:Ачыстка і хімічнае ўмацаванне.

-

Thin-Film Deposition:Пласты SiO₂, SiN і ITO.

-

Photolithography:4–6 масак для вызначэння піксельных масіваў.

-

Cell Assembly:Упырскванне і герметызацыя вадкіх крышталяў.

-

Інтэграцыя падсветкі:Для падсветкі дададзеныя святлодыёдныя або CCFL-падсветкі.

Этапы вытворчасці OLED

-

Выбар субстрата:Шкляныя або палімерныя плёнкі для гнуткасці.

-

Вакуумнае нанясенне:Арганічныя матэрыялы (напрыклад, эмітэры TADF), нанесеныя з дапамогай струменевага друку або тэрмічнага выпарэння.

-

Інкапсуляцыя:Герметызацыя тонкаплёнкавымі бар'ерамі для прадухілення траплення вільгаці.

-

Інтэграцыя мікрасхемы драйвера:TFT-матрыцы кантралююць яркасць і колер пікселяў.

Параўнальныя паказчыкі

| Параметр | TFT-LCD | ТЫ ЁСЦЬ |

|---|---|---|

| Яркасць | 300–800 кд/м² | 500–1000 кд/м² |

| Час водгуку | 5–8 мс | 0,1 мс |

| Спажыванне энергіі | 3–5 Вт (10-цалевы экран) | 2–4 Вт (10-цалевы экран) |

| Ураджайнасць | ~75% | ~60% |

5. Leading Factories and Case Studies

Лінія B1 кампаніі BOE (Пекін)

Праект:Інтэграцыя міні-святлодыёдаў для падсветкі ВК-дысплеяў.

Вынік:Дасягнута ёмістасць TFT-LCD 100 тыс./м² з пераўтварэннем Mini LED 9 тыс./м², што павысіла эфектыўнасць падсветкі на 30%.

Лінія Т4 CSOT (Ухань)

Фокус:Вытворчасць AMOLED-дысплеяў для аўтамабільных дысплеяў.

Ёмістасць:48 тыс./м² з яркасцю 1000 кд/м².

Тэхналогія:Выкарыстоўвае TFT-схемы на аснове Cu для паляпшэння праводнасці.

Лінейка Visionox V3 (Чэнду)

Інавацыі:Надрукаваныя OLED-дысплеі з выкарыстаннем тэхналогіі струменевай друку.

Зніжэнне выдаткаў:Скарачае колькасць адходаў матэрыялаў на 40%, арыентуючыся на масавае ўкараненне на рынку.

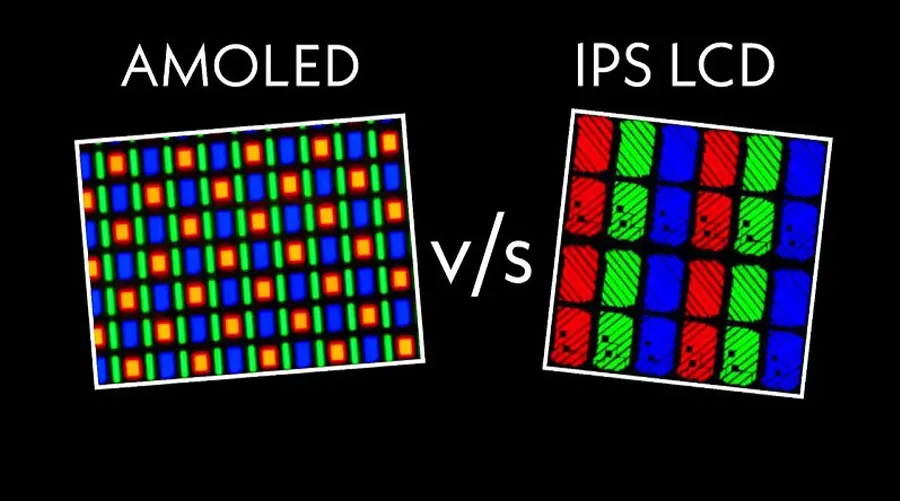

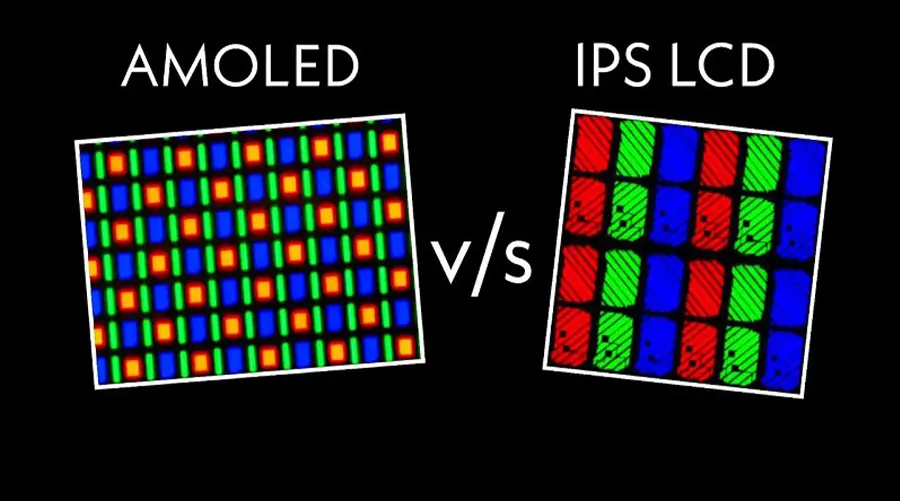

6. TFT vs OLED: A Detailed Comparison

Паказчыкі прадукцыйнасці

| Асаблівасць | TFT-LCD | ТЫ ЁСЦЬ |

|---|---|---|

| Дакладнасць колеру | Крыху ніжэй (8 біт) | Палепшаны (10-бітны) |

| Кут агляду | 120–140° | 170°+ |

| Частата абнаўлення | 60–120 Гц | 60–120 Гц |

| Даўгавечнасць | Большы тэрмін службы | Схільны да выгарання |

Доля рынку (2023 г.)

TFT-ВК-дысплей:65% сусветных паставак дысплеяў (выкарыстоўваюцца ў тэлевізарах, маніторах).

ВЫ:35% паставак сканцэнтравана на смартфонах і носных прыладах.

7. Future Trends and Innovations

Мікрасвятлодыёдныя дысплеі

Лінія B1 Банка Англіі:Вырабляе мініяцюрныя святлодыёдныя падсветкі для ВК-дысплеяў, дасягаючы 20 000 м² у год.

QD-OLED ад Samsung:Спалучае квантавыя кропкі з OLED для павышэння яркасці.

LTPO для AMOLED

Лінія Т6 ад CSOT:Рэалізуе LTPO (нізкатэмпературны полікрышталічны аксід) для частаты абнаўлення 120 Гц і дынамічнай карэкціроўкі частаты кадраў.

Друкаваны OLED-дысплей

Лінейка Vistar ад Visionox:Эксперыменты са струменевым друкам для зніжэння выдаткаў і маштабавання вытворчасці.

8. FAQs About TFT and OLED

Пытанне 1: У чым розніца паміж TFT-трафікамі a-Si і LTPS?

a-Si (аморфны крэмній):Эканамічна выгадны для вялікіх панэляў (напрыклад, тэлевізараў).

LTPS (нізкатэмпературны полікрышталічны крэмній):Больш высокая рухомасць электронаў для невялікіх дысплеяў з высокім разрозненнем (напрыклад, смартфонаў).

Пытанне 2: Чаму OLED-дысплеі даражэйшыя за TFT-LCD-дысплеі?

Вакуумнае нанясенне:Складаны і дарагі працэс атрымання арганічных матэрыялаў.

Выдаткі на матэрыялы:Фасфарэсцэнтныя выпраменьвальнікі і матэрыялы для інкапсуляцыі павялічваюць выдаткі.

Пытанне 3: Як працэсы вытворчасці Cu паляпшаюць прадукцыйнасць OLED?

Медзь (Cu) замяняе алюміній (Al) у схемах TFT, паляпшаючы праводнасць і стабільнасць дысплеяў з высокай частатой абнаўлення.

Latest articles

-

Чаму 1–2-цалевыя AMOLED-дысплеі з'яўляюцца ключавымі для AR/XR у 2025 годзе

Чаму 1-2-цалевыя AMOLED-дысплеі становяцца неабходнымі ў буме AR/XR (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Расцягнутыя ВК-дысплеі для рознічнага гандлю: павелічэнне продажаў і ўзаемадзеяння ў супермаркетах

Даведайцеся, як расцягнутыя ВК-дысплеі паляпшаюць маркетынг на паліцах супермаркетаў, павялічваюць продажы, скарачаюць

-

Расцягнутыя ВК-рашэнні для рэстаранаў і гасцінічных устаноў

Расцягнутыя ВК-дысплеі прапануюць элегантныя дысплеі высокай яркасці, ідэальна падыходзяць для меню рэстаранаў і гасцінічных устаноў.

Рэкамендаваныя прадукты

-

7,0-цалевы IPS TFT з высокай яркасцю без сэнсарнага экрана

BR070JII 2757-B4 V.1 Уводзіны Гэты выключны 7,0-цалевы TFT LCD-модуль працуе на базе a-Si TFT act

-

10,1-цалевы TFT-інтэрфейс IPS LVDS без сэнсарнага экрана

BR101DHI3625-A4 V.1 Уводзіны Вядома. BR101DHI3625-A4 V.1 - гэта ўдасканалены TFT LCD-модуль, які вылучаецца...

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Тэхнічныя характарыстыкі прадукту: BRO392001A Разрозненне: 1080x1024 Дыяпазон працоўнага напружання: 28 В Памер экрана: 3,92

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Тэхнічныя характарыстыкі прадукту: BRO548001A Разрозненне: 1080x1920 Дыяпазон працоўнага напружання: 2,8 В Памер экрана: 5,4