Inhoudsopgave

1. Introduction to TFT and OLED

Thin-Film Transistor (TFT) and Organic Light-Emitting Diode (OLED) technologies are the cornerstones of modern display innovation. TFT-LCDs dominate the market for large-format screens like TVs and monitors, while OLEDs lead in high-end smartphones, wearables, and flexible displays. This article explores the science, manufacturing, and real-world applications of these technologies, leveraging insights from leading Chinese manufacturers such as BOE, CSOT, and Visionox.

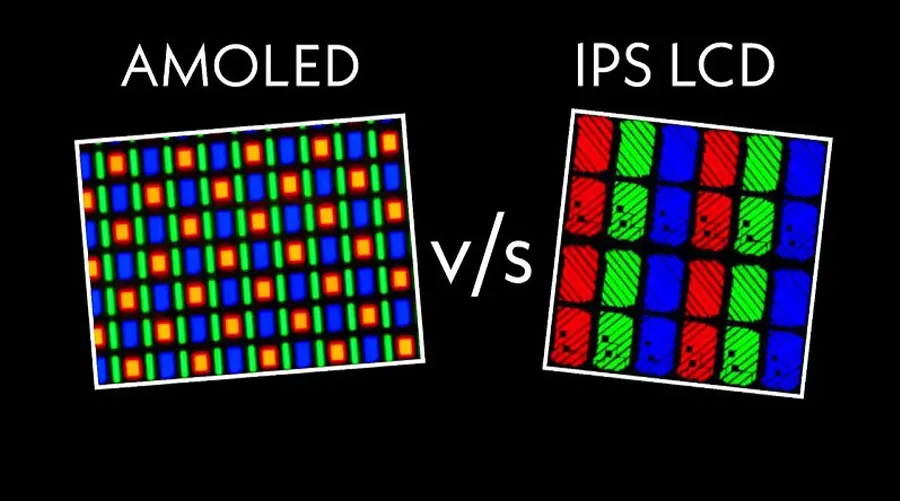

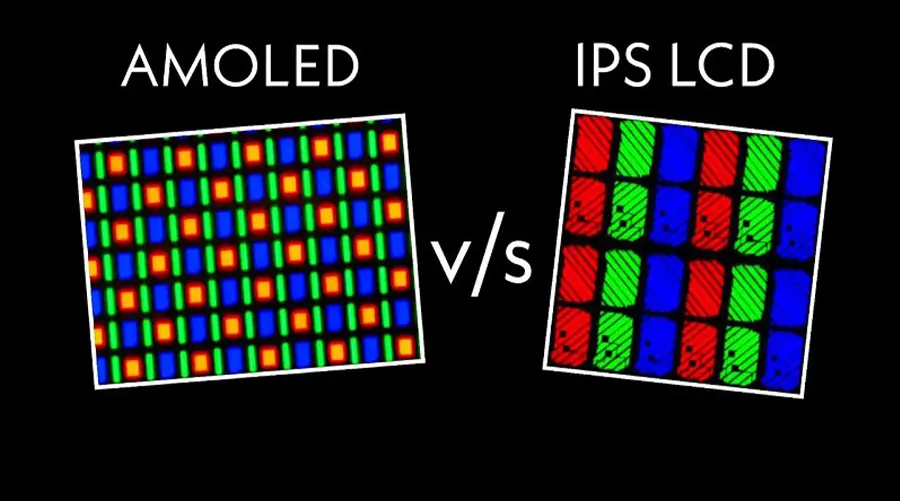

Key Differences at a Glance

| Functie | TFT-LCD | JIJ BENT |

|---|---|---|

| Backlight Required | Yes (LED/CCFL) | No (self-emissive) |

| Contrastverhouding | ~500:1 | Up to 1,000,000:1 |

| Flexibiliteit | Rigid panels | Flexible/foldable designs |

| Energie-efficiëntie | Gematigd | High for dark content |

| Kosten | $15–$30/cm² | $30–$50/cm² |

2. TFT Technology: Principles and Applications

What is TFT?

TFT (Thin-Film Transistor) is a semiconductor technology used in LCDs (Liquid Crystal Displays) to control individual pixels. TFT-LCDs combine a liquid crystal layer with a backlight and a TFT array to produce high-resolution images.

Key Components of TFT-LCDs

-

Glass Substrates: Typically 700–1200mm in size, made of soda-lime or alkali-free glass.

-

Thin-Film Deposition: Layers of silicon dioxide (SiO₂), silicon nitride (SiN), and indium tin oxide (ITO) are deposited via chemical vapor deposition (CVD).

-

Photolithography: A multi-step process using 4–6 masks to pattern the TFT array.

-

Cell Assembly: Liquid crystals are sealed between two substrates with spacers to maintain uniform thickness.

Applications of TFT-LCDs

-

Television and Monitor Manufacturing: Dominates the TV market due to cost-effectiveness.

-

Industrial Automation: Used in medical devices (e.g., diagnostic equipment) and industrial control panels.

-

Autodisplays: Integrated into car dashboards and infotainment systems.

Case Study: BOE's B7 Line

BOE’s B7 line in Chengdu produces 48K/M AMOLED panels using LTPS (Low-Temperature Polycrystalline Silicon) technology. This line achieves 1000 cd/m² brightness and supports 120Hz refresh rates, making it ideal for high-end smartphones.

3. OLED Technology: Advantages and Challenges

What is OLED?

OLED (Organic Light-Emitting Diode) uses organic compounds that emit light when electrically stimulated. Unlike TFT-LCDs, OLEDs do not require a backlight, enabling ultra-thin, flexible displays with perfect blacks and wide viewing angles.

Voordelen van OLED

-

Hoge contrastverhouding: Achieves 1,000,000:1 due to self-emissive pixels.

-

Flexibility: Enables foldable phones (e.g., Huawei Mate X3) and curved TVs.

-

Energie-efficiëntie: Consumes less power for dark scenes compared to TFT-LCDs.

Challenges in OLED Manufacturing

-

Blue OLED Lifespan:Blauwe organische materialen degraderen sneller dan rode/groene materialen, waarvoor geavanceerde fosforescerende emitters nodig zijn.

-

Productiekosten:Vacuümdepositieprocessen zijn duur: de kosten kunnen oplopen tot $ 30–$ 50/cm².

-

Opbrengstpercentages:Lager dan TFT-LCD's (doorgaans 60–70% vanwege materiaalfouten).

Case Study: Visionox's V2-lijn

De V2-lijn van Visionox in Guangzhou richt zich op AMOLED-productie met Cu (koper) en LTPO (lagetemperatuurpolykristallijnoxide)-technologieën. Deze lijn ondersteunt FDA-gecertificeerde medische apparaten en autodisplays en bereikt in 2023 een capaciteit van 30.000 m³/m³.

4. Manufacturing Processes of TFT and OLED

TFT-LCD-productiestappen

-

Voorbereiding van het glazen substraat:Reinigend en chemisch versterkend.

-

Thin-Film Deposition:Lagen van SiO₂, SiN en ITO.

-

Photolithography:4–6 maskers om pixelarrays te definiëren.

-

Cell Assembly:Injectie en afdichting van vloeibare kristallen.

-

Integratie van achtergrondverlichting:LED- of CCFL-achtergrondverlichting toegevoegd voor verlichting.

OLED-productiestappen

-

Substraatselectie:Glas- of polymeerfolies voor flexibiliteit.

-

Vacuümdepositie:Organische materialen (bijvoorbeeld TADF-stralers) die via inkjetprinten of thermische verdamping worden afgezet.

-

Inkapseling:Afdichten met dunne-filmbarrières om vochtinfiltratie te voorkomen.

-

Driver IC-integratie:TFT-arrays regelen de helderheid en kleur van pixels.

Vergelijkende statistieken

| Parameter | TFT-LCD | JIJ BENT |

|---|---|---|

| Helderheid | 300–800 cd/m² | 500–1000 cd/m² |

| Reactietijd | 5–8 ms | 0,1 ms |

| Stroomverbruik | 3–5 W (10-inch scherm) | 2–4 W (10-inch scherm) |

| Opbrengstpercentage | ~75% | ~60% |

5. Leading Factories and Case Studies

BOE's B1-lijn (Peking)

Project:Mini LED-integratie voor LCD-achtergrondverlichting.

Resultaat:Bereikte een capaciteit van 100K/M TFT-LCD met 9K/M Mini LED-conversie, waardoor de achtergrondverlichtingsefficiëntie met 30% werd verhoogd.

CSOT's T4-lijn (Wuhan)

Focus:AMOLED-productie voor autodisplays.

Capaciteit:48K/M met 1000 cd/m² helderheid.

Technologie:Maakt gebruik van op koper gebaseerde TFT-circuits voor verbeterde geleiding.

Visionox's V3-lijn (Chengdu)

Innovatie:Geprint OLED met inkjettechnologie.

Kostenreductie:Vermindert materiaalverspilling met 40% en richt zich op massamarktacceptatie.

6. TFT vs OLED: A Detailed Comparison

Prestatiegegevens

| Functie | TFT-LCD | JIJ BENT |

|---|---|---|

| Kleurnauwkeurigheid | Iets lager (8-bit) | Superieur (10-bits) |

| Kijkhoek | 120–140° | 170°+ |

| Vernieuwingsfrequentie | 60–120 Hz | 60–120 Hz |

| Duurzaamheid | Langere levensduur | Gevoelig voor inbranden |

Marktaandeel (2023)

TFT-LCD:65% van de wereldwijde displayleveringen (gebruikt in tv's en monitoren).

JIJ BENT:35% van de zendingen bestaat uit smartphones en wearables.

7. Future Trends and Innovations

MicroLED-schermen

B1-lijn van BOE:Produceert Mini LED-achtergrondverlichting voor LCD's, met een jaarlijkse productie van 20.000 m².

De QD-OLED van Samsung:Combineert quantum dots met OLED voor verbeterde helderheid.

LTPO voor AMOLED

De T6-lijn van CSOT:Implementeert LTPO (Low-Temperature Polycrystalline Oxide) voor vernieuwingsfrequenties van 120 Hz en dynamische aanpassingen van de framesnelheid.

Gedrukte OLED

De Vistar-lijn van Visionox:Experimenten met inkjetprinten om kosten te verlagen en de productie op te schalen.

8. FAQs About TFT and OLED

V1: Wat is het verschil tussen a-Si en LTPS TFT's?

a-Si (amorf silicium):Kosteneffectief voor grote panelen (bijv. tv's).

LTPS (Lage-temperatuur polykristallijn silicium):Hogere elektronenmobiliteit voor kleine, hoge-resolutie displays (bijv. smartphones).

Vraag 2: Waarom zijn OLED's duurder dan TFT-LCD's?

Vacuümdepositie:Complex en kostbaar proces voor organische materialen.

Materiaalkosten:Fosforescerende emitters en inkapselingsmaterialen verhogen de kosten.

Vraag 3: Hoe verbeteren Cu-processen de OLED-prestaties?

Koper (Cu) vervangt aluminium (Al) in TFT-circuits en verbetert de geleiding en stabiliteit van beeldschermen met een hoge verversingssnelheid.

Laatste artikelen

-

Waarom 1-2" AMOLED's de sleutel zijn tot AR/XR in 2025

Waarom 1-2 inch AMOLED-schermen essentieel worden in de AR/XR-hausse (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

LCD-schermen met uitgerekte staven voor de detailhandel: verhoog de omzet en betrokkenheid in supermarkten

Ontdek hoe LCD-schermen met uitgerekte staven de marketing in de supermarktschappen verbeteren, de verkoop stimuleren en de kosten verlagen.

-

Uitgerekte LCD-oplossingen voor restaurants en horecagelegenheden

Uitgerekte LCD's bieden strakke, zeer heldere displays die perfect zijn voor restaurantmenu's en horecagelegenheden.

Aanbevolen producten

-

7,0 inch IPS TFT met hoge helderheid zonder touchscreen

BR070JII 2757-B4 V.1 InleidingDeze uitzonderlijke 7,0-inch TFT LCD-module, aangedreven door een a-Si TFT-act

-

10,1 inch IPS LVDS-interface TFT zonder touchscreen

BR101DHI3625-A4 V.1 Inleiding Zeker. BR101DHI3625-A4 V.1 is een geavanceerde TFT LCD-module die

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Productspecificaties: BRO392001A Resolutie: 1080x1024 Bedrijfsspanningsbereik: 28V Schermgrootte: 3,92

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Productspecificaties: BRO548001A Resolutie: 1080x1920 Bedrijfsspanningsbereik: 2,8V Schermgrootte: 5,4