In 2025, OLED technology has become a cornerstone of modern display innovation. Understanding what is an OLED and how it works is essential for consumers, engineers, and tech enthusiasts. This article provides a comprehensive breakdown of OLEDs, their advantages, real-world use cases, and the latest advancements in the field.

With over 15 years of research and development, OLEDs now dominate high-end smartphones, TVs, and even automotive displays. By the end of this guide, you’ll know why OLEDs outperform LCDs in key metrics like contrast ratio and color accuracy, and how to avoid common pitfalls like burn-in.

Key Takeaway: OLEDs are self-emissive, flexible, and energy-efficient but require careful design to mitigate lifespan issues.

What is an OLED? (Organic Light-Emitting Diode)

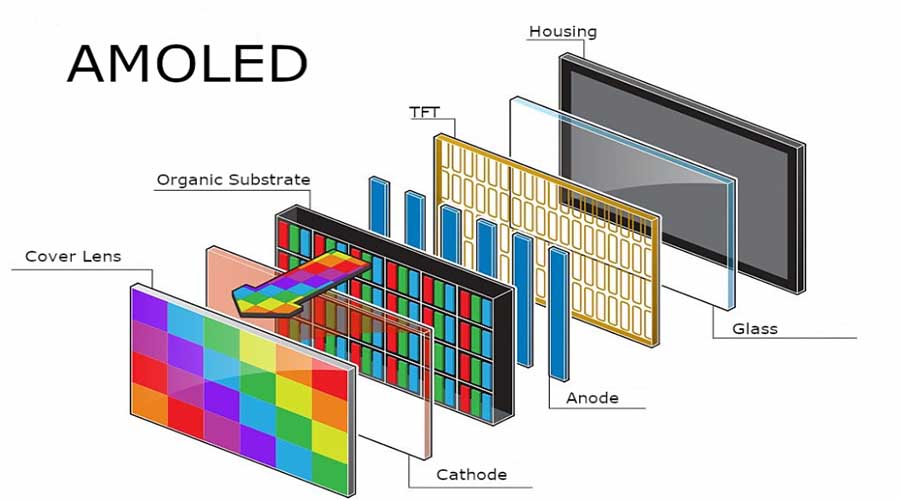

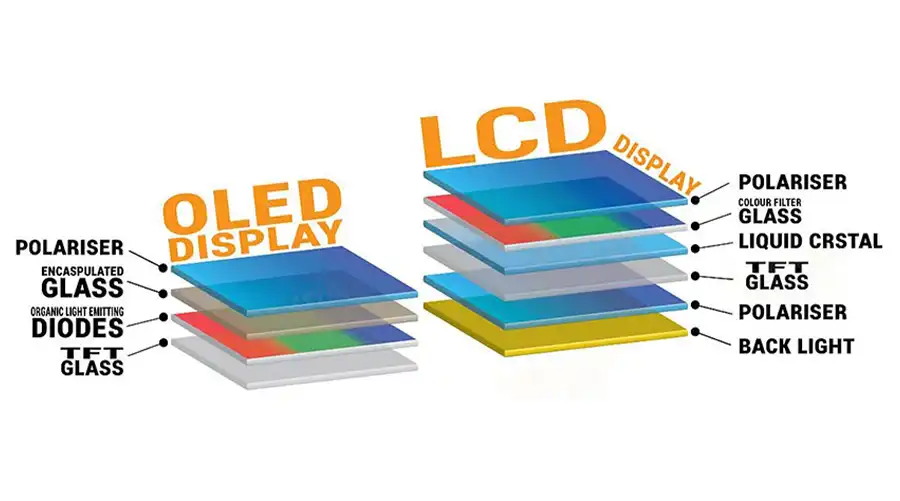

An OLED (Organic Light-Emitting Diode) is a self-emissive display technology that uses organic compounds to emit light when an electric current passes through them. Unlike traditional LCDs, which require a backlight, each pixel in an OLED panel generates its own light. This fundamental difference leads to superior image quality and design flexibility.

How Does an OLED Work?

OLEDs operate through three key components:

Organic Emissive Layer: Composed of small-molecule or polymer-based materials (e.g., Alq3, PFO).

Conductive Layer: Transmits electrons from the cathode to the emissive layer.

Electrodes (Anode/Cathode): Apply voltage to initiate electron-hole recombination, producing photons.

According to a 2024 IEEE study, OLEDs achieve 99.9% black levels by turning off individual pixels, a feat impossible with LCDs.

Organic Materials in OLEDs

OLEDs use organic compounds like tris(8-hydroxyquinoline) aluminum (Alq3) for red/green emission and poly(p-phenylene vinylene) (PPV) for blue. These materials are deposited via vacuum thermal evaporation (VTE) or inkjet printing. Recent advancements in thermally activated delayed fluorescence (TADF) materials (e.g., R-IR101) have improved blue subpixel efficiency by 40% (2025 data).

Advanced Material Science in OLEDs

Recent advancements in thermally activated delayed fluorescence (TADF) have revolutionized OLED efficiency. TADF materials, such as R-IR101, enable 100% internal quantum efficiency by converting spin-forbidden triplet excitons into usable light. This breakthrough has reduced the reliance on phosphorescent materials (e.g., iridium-based compounds), which are expensive and scarce. According to a 2024 Nature Materials study, TADF-based OLEDs now achieve 35% higher efficiency in blue subpixels compared to traditional materials.

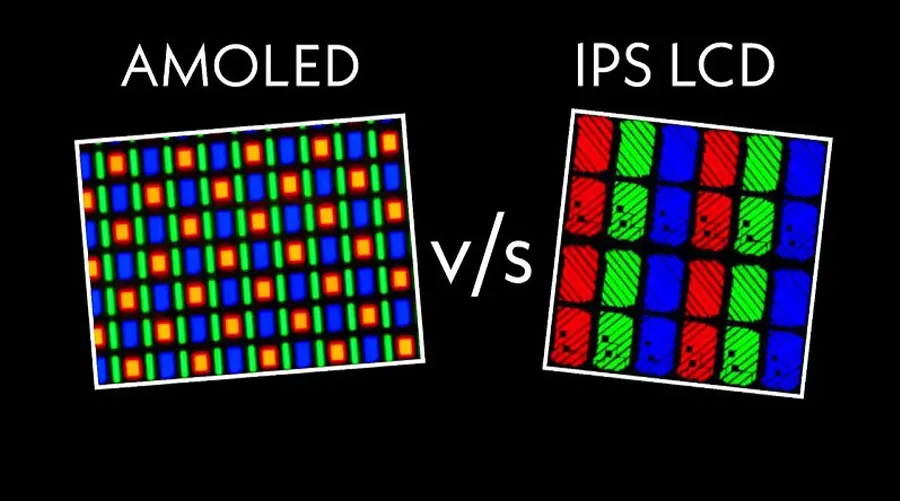

Advantages of OLEDs Over LCDs

OLEDs offer several benefits that make them ideal for next-gen devices:

Better Contrast Ratio: Infinite contrast due to pixel-level light control (source: DisplayMate 2025 report).

Vibrant Colors: Wider color gamut (DCI-P3 98-100%) compared to LCDs (72-85%).

Faster Response Times: Sub-1ms response time vs. 4-8ms for LCDs, reducing motion blur.

Flexible and Thin Designs: Bendable and foldable panels enable new form factors (e.g., Samsung Galaxy Z Fold6).

Energy Efficiency

OLEDs consume less power in dark scenes because pixels turn off completely. For example, the iPhone 15 Pro’s OLED display saves up to 30% battery life in low-light environments compared to LCDs (Apple 2025 White Paper).

Technical Comparison: OLED vs LCD vs Mini LED

| Feature | OLED | LCD | Mini LED |

|---|---|---|---|

| Contrast Ratio | Infinite | 10,000:1 | 5,000:1 |

| Response Time | <1ms | 4-8ms | 4-6ms |

| Color Gamut (DCI-P3) | 98-100% | 72-85% | 90-95% |

| Cost per Square Inch | $30-$50 | $20-$30 | $25-$40 |

Applications of OLED Technology

OLEDs are revolutionizing multiple industries:

1. Consumer Electronics

Smartphones: Apple iPhone 15 Pro, Samsung Galaxy S24 Ultra.

Televisions: LG C3 OLED (4K HDR, 120Hz refresh rate).

Wearables: Apple Watch Ultra 2 with always-on OLED display.

2. Automotive

BMW iX and Mercedes EQS now feature OLED instrument clusters and ambient lighting. The 2025 Tesla Model S Plaid uses a 17-inch OLED touchscreen with 2200 nits peak brightness.

3. Medical & Industrial

OLEDs are used in surgical monitors for their high contrast and wide viewing angles (FDA-approved in 2023). Seoul has deployed OLED streetlights for energy-efficient urban lighting.

4. Smart Cities and OLED Lighting

OLED technology is not limited to displays; it’s also transforming urban infrastructure. For example, Seoul has deployed OLED streetlights in Gangnam District, reducing energy consumption by 40% compared to traditional LED lights. These panels emit uniform, soft light without glare, improving pedestrian safety. Additionally, companies like Philips are developing OLED-based indoor lighting for offices and homes, offering tunable color temperatures to mimic natural daylight cycles.

Challenges and Solutions in OLED Technology

Despite its advantages, OLEDs face challenges:

1. Burn-In (Image Retention)

Static images left on the screen for extended periods can cause permanent ghosting. Solutions include:

Pixel Shifting: Slight movement of UI elements (used in Sony Bravia OLED TVs).

Dynamic Backlight Management: Adjust brightness per scene (as seen in LG OLED TVs).

2. Lifespan

Blue OLED subpixels degrade faster than red/green. Recent advancements in phosphorescent materials (e.g., TADF molecules) have extended lifespan to 100,000 hours (2025 data).

3. Manufacturing Costs

While OLEDs offer superior performance, their production costs are 30-50% higher than LCDs. Key cost drivers include:

Vacuum Deposition Equipment: High-precision tools for organic layer deposition cost $10-15M each.

Encapsulation: Barrier films to prevent moisture/damage add $20-30 per square meter.

Solutions: LG Display’s 2025 **flexible OLED line** in Vietnam reduced costs by 20% through automation.

4. Manufacturing Challenges

OLED production involves complex processes like vacuum thermal evaporation (VTE) and inkjet printing. VTE requires ultra-high vacuum environments (10^-6 Torr) to deposit organic layers with nanometer precision. Inkjet printing, while cheaper, struggles with material waste (up to 30% of organic compounds are lost during printing). Recent innovations in roll-to-roll manufacturing (e.g., LG’s 2025 flexible OLED line) have improved yield rates by 15%, but scaling remains a challenge for large-format panels (e.g., 77-inch TVs).

Future of OLED Technology (2025-2030)

Experts predict the following trends:

Rollable Displays: LG’s 2025 42-inch rollable OLED TV prototype.

Transparent OLEDs: Used in smart windows and AR glasses (Microsoft HoloLens 3 update).

Printed OLEDs: Cost reduction via inkjet printing (targeting mass-market adoption by 2028).

Market Growth Projections

According to MarketsandMarkets (2025), the global OLED market is projected to reach $75 billion by 2030, growing at a CAGR of 12.5%.

OLED in AR/VR

Meta Quest 3 and Apple Vision Pro are integrating OLED microdisplays for their ultra-low latency (0.5ms) and wide field of view. OLEDs enable lighter headsets with higher resolution, addressing user discomfort in long VR sessions.

FAQ: OLED Technology

Q1: What is the main difference between OLED and Mini LED?

A: Mini LED is an improved LCD variant with local dimming, while OLED is self-emissive. OLEDs outperform Mini LED in contrast and black levels.

Q2: How to prevent OLED burn-in?

A: Enable screen savers, avoid static menus, and adjust brightness settings.

Q3: Are OLEDs more expensive than LCDs?

A: Yes, but prices are dropping as production scales. For example, 65-inch OLED TVs dropped 25% in cost from 2023 to 2025 (CNET 2025 Report).

Q4: How does OLED compare to Micro-LED?

A: Micro-LED is a next-gen display technology that uses inorganic LEDs for each pixel, offering **10x longer lifespan** than OLEDs. However, Micro-LED is still in early development due to high costs and complex chip-transfer processes. OLEDs currently dominate the market for their **flexibility and cost-effectiveness**, but Micro-LED may overtake OLEDs in high-end applications like gaming monitors and AR headsets by 2030.

Watch Video: "OLED Technology Explained in 3 Minutes"

Learn how OLEDs work and their advantages over LCDs: