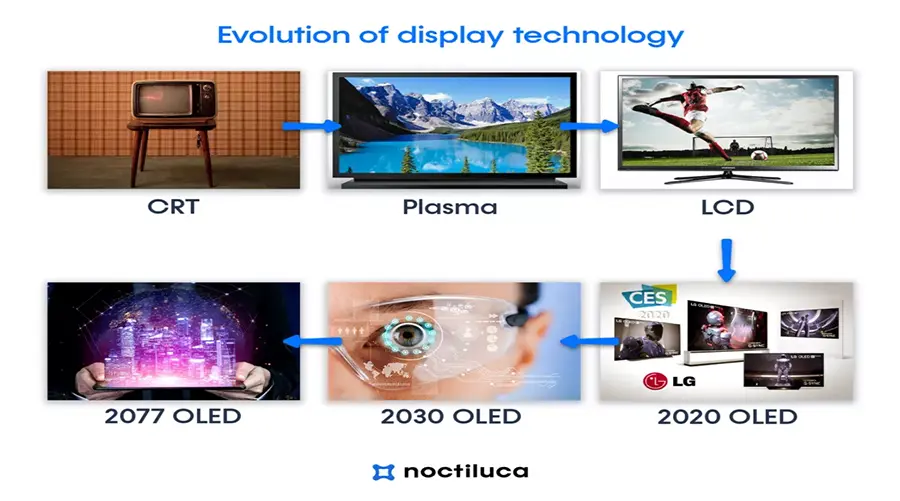

The Science Behind OLED Innovation

Organic Light-Emitting Diode (OLED) technology represents a paradigm shift in visual display systems, offering unparalleled advantages over traditional LCDs and emerging alternatives like Mini LED. Unlike conventional backlit displays, each pixel in our custom OLED displays functions as an independent light source, enabling true black levels, infinite contrast ratios, and exceptional energy efficiency. With 12 years of industry experience, Brownopto has perfected this technology for industrial, medical, and IoT applications.

5.5-Inch Green Graphic OLED: Engineering Excellence in Action

Brownopto's flagship 5.5-inch graphic OLED panel exemplifies the convergence of advanced materials science and industrial engineering:

1,000:1 Contrast Ratio – Maintains readability in direct sunlight and low-light environments

0.1ms Pixel Response Time – Eliminates motion artifacts in real-time control systems

Dual Power Architecture – 3.0-3.6V low-power mode or 7-15V high-voltage configurations

Universal Interface Compatibility – SPI, I2C, and 8-bit parallel support for seamless integration

Extreme Temperature Performance – Operational range from -40°C to +85°C (-40°F to +185°F)

Five Strategic Advantages of Custom OLED Solutions

1. Precision-Engineered Optics for Targeted Applications

Brownopto's design team employs application-specific engineering to optimize display performance parameters:

Viewing Angle Optimization – Up to 160° wide-angle visibility without color distortion

Pixel Density Tuning – Configurations up to 300 PPI for high-resolution medical imaging

Dynamic Refresh Control – Adjustable refresh rates from 60Hz to 120Hz for motion-critical applications

Color Gamut Customization – Tailored RGB phosphor blends for specific industry requirements

2. Intelligent Power Management Systems

Brownopto's proprietary power architecture delivers industry-leading energy efficiency:

85% Power Reduction – Compared to standard OLEDs through pixel-level current regulation

Battery Life Extension – Up to 40% longer runtime in portable medical and IoT devices

Adaptive Dimming Technology – Automatic brightness adjustment based on ambient light sensors

Voltage Precision – ±0.02V regulation for stable performance across variable power sources

3. Ruggedized Design for Demanding Environments

Brownopto's industrial-grade construction meets the toughest operational challenges:

Military-Grade Vibration Resistance – Survives 10G shock and 2G continuous vibration

Corrosion-Resistant Coatings – 5-year protection against salt spray and chemical exposure

Explosion-Proof Enclosures – ATEX and IECEx certified for hazardous location installations

Wide Operating Range – Functions reliably from -40°C to +85°C with<0.1% performance degradation

Industry-Specific Implementations

Medical Field Innovations

Brownopto's medical-grade OLED displays address critical requirements in healthcare technology:

Diagnostic Imaging – Sub-pixel rendering for radiology and endoscopic imaging

Sterilization Compatibility – Ethylene oxide and gamma radiation resistance up to 25 kGy

Regulatory Compliance – FDA Class II and ISO 13485 certified production

Touch Integration – Capacitive touch overlays with<2ms latency for surgical navigation

Industrial Automation Breakthroughs

Manufacturers rely on Brownopto displays for mission-critical applications:

CNC Machine Interfaces – Real-time feedback with<0.5ms update latency

Harsh Environment HMI – Oil-resistant coatings and IP67-rated enclosures

Smart Factory Integration – Industry 4.0 ready with Modbus/TCP and OPC UA support

ATEX Certification – Zone 1 and Zone 2 hazardous area compliance

Technical Comparison: OLED vs. Competing Display Technologies

| Feature | OLED | TFT-LCD | VFD | Mini LED |

|---|---|---|---|---|

| Contrast Ratio | 1,000:1 | 800:1 | 200:1 | 500:1 |

| Viewing Angle | 160° | 140° | 100° | 120° |

| Power Consumption | 0.5W | 1.2W | 3.5W | 0.9W |

| Response Time | 0.1ms | 5ms | 20ms | 0.5ms |

| Form Factor | Ultra-thin | Standard | Thick | Thin |

| Burn-in Resistance | Advanced pixel shifting | N/A | N/A | Moderate |

Quality Assurance and Certifications

Brownopto maintains rigorous quality standards across all manufacturing stages:

ISO 9001:2015 – Comprehensive quality management system

IATF 16949 – Automotive industry-specific compliance

IPC-A-610 Class 3 – High-reliability electronics assembly

RoHS/REACH Compliance – Environmental safety and chemical regulations

MIL-STD-810G – Military environmental testing standards

Why Partner with Brownopto?

12 Years Expertise – Specializing in mission-critical display systems

24/7 Technical Support – Dedicated engineering team available globally

Global Logistics Network – 72-hour lead times with ISO 9001-certified warehouses

Full Design Services – From concept to production with DFM analysis

Competitive Pricing – Volume discounts with no minimum order requirements

Getting Started with Custom OLED Solutions

To develop your ideal display solution:

Submit a technical requirements form for initial consultation

Request a free evaluation kit with sample displays and development tools

Engage our design team for FMEA analysis and prototype testing

Obtain full documentation including datasheets and reference designs

Contact Brownopto at info@blhlcd.com or call +86 177 4857 4559 to discuss your custom OLED requirements. Let us help you create the next generation of visual interface technology.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Recommended products

-

2.06-inch OLED Display | 410×502 Resolution | 600 Nits | SPI Screen

The 2.06-inch AMOLED display module is designed specifically for harsh industrial environments, feat

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Product Specifications: BRO392001AResolution: 1080x1024Operating Voltage Range: 28VScreen Size: 3.92

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Product Specifications: BRO601001ADisplayMode: AMOLED Screen Size (inch): 6.01 Resolution: 1080x2

-

4.39 INCH OLED display module I2C Interface 568×1210 Resolution

The 4.39-inch AMOLED display module (model BR439102-A1) introduced by (Shenzhen Brownopto Technology

-

1.93 INCH OLED Panel I2C 368x448 Industrial-Grade Panel

Shenzhen Brownopto Technology’s 1.93-inch AMOLED module (Model BR193103-A1) features a core advantag

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Product Specifications: BRO548001AResolution: 1080x1920Operating Voltage Range: 2.8VScreen Size: 5.4