Introduction to OLED Technology

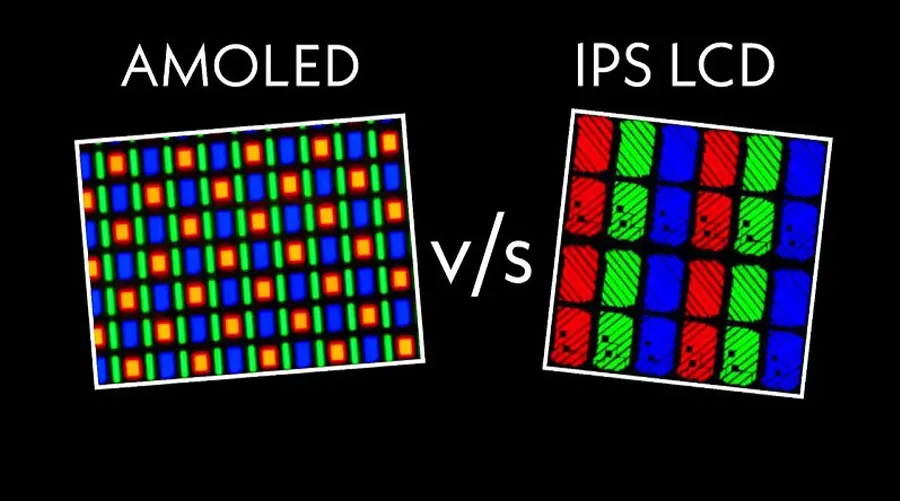

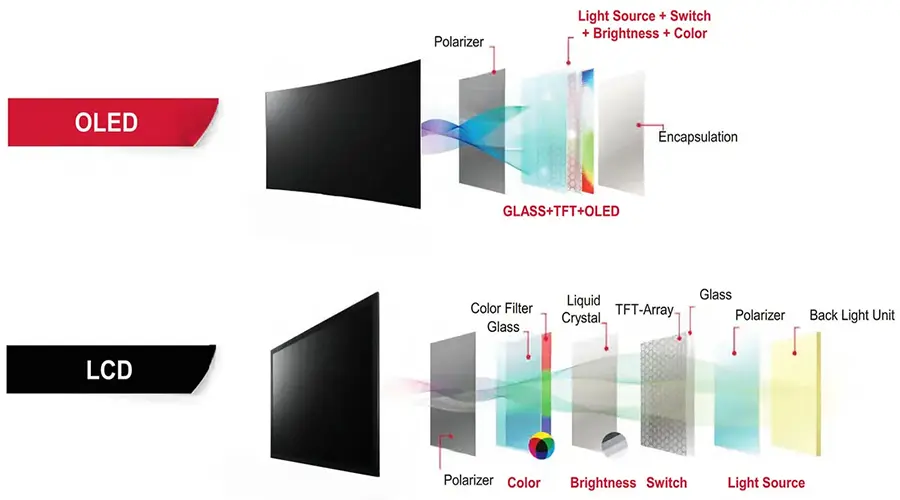

OLED (Organic Light-Emitting Diode) technology has revolutionized the display industry by offering self-emissive, ultra-thin, and energy-efficient screens. Unlike traditional LCDs that rely on backlighting, OLED displays use organic materials to generate light directly at each pixel. This breakthrough has enabled innovations such as flexible, transparent, and curved screens, making OLED a cornerstone of modern electronics. With companies like Brownopto leading advancements in OLED materials and manufacturing, the technology continues to redefine visual experiences across industries.

The Evolution of OLED Displays

The journey of OLED technology began in the 1970s when researchers discovered that certain organic compounds could emit light when an electric current was applied. By the 1980s, key milestones were achieved, including the development of the first practical OLED by Ching Tang and Steven Van Slyke at Eastman Kodak. Over the decades, advancements in organic materials, vacuum deposition techniques, and circuit design transformed OLED from a scientific curiosity into a commercial reality.

Today, OLED displays power smartphones, TVs, wearables, and automotive interfaces. Companies like Brownopto have played a pivotal role in scaling production and improving performance. For example, Brownopto OLED panels now feature enhanced color accuracy, longer lifespans, and reduced power consumption, addressing early limitations of the technology.

How OLED Displays Work

The Science Behind Organic Light-Emitting Diodes

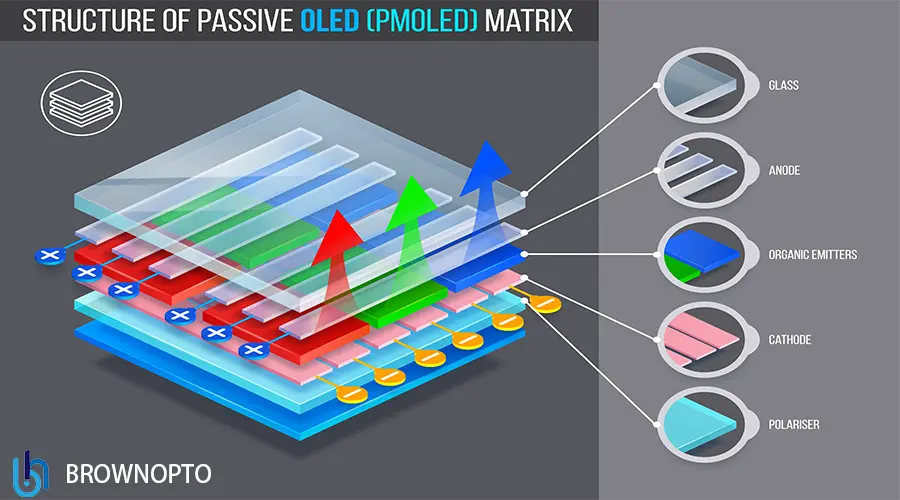

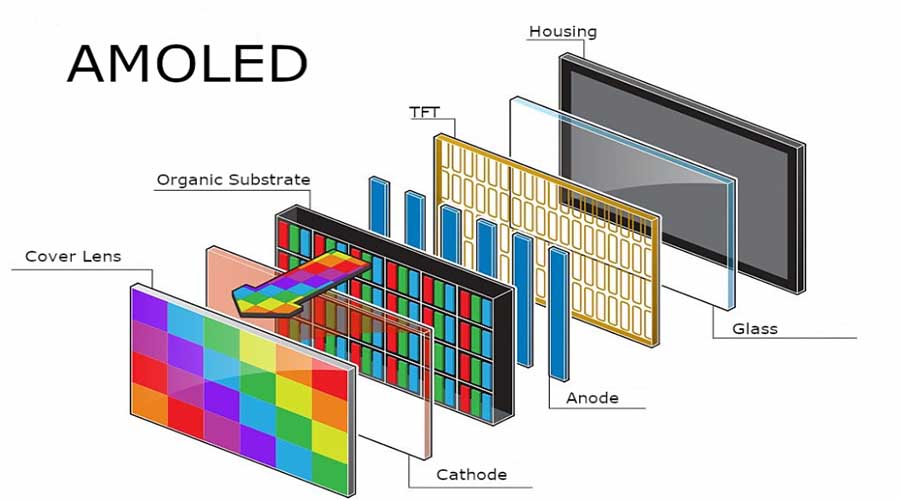

OLED technology operates on the principle of electroluminescence. When an electric current is applied to an OLED panel, electrons and holes (positive charges) are injected into organic layers between two electrodes (an anode and a cathode). These charge carriers recombine in the emissive layer, creating excitons—energy states that emit photons when they decay. This process allows each pixel to emit its own light, eliminating the need for backlighting and enabling superior contrast and flexibility.

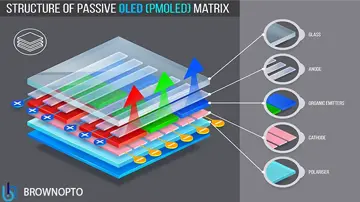

Key Components of an OLED Display

Anode (Cathode): Transparent electrode (typically ITO) that allows light to pass through.

Hole Transport Layer (HTL): Facilitates the movement of holes from the anode to the emissive layer.

Emissive Layer: Contains organic molecules that emit light when electrons and holes recombine.

Electron Transport Layer (ETL): Helps electrons move from the cathode to the emissive layer.

Brownopto OLED Innovations

Brownopto has pioneered advancements in OLED materials and encapsulation techniques. For instance, their proprietary phosphorescent organic materials (PHOLED) achieve 100% internal quantum efficiency, significantly improving brightness and energy efficiency. Additionally, Brownopto’s moisture-resistant encapsulation extends the lifespan of OLED displays in harsh environments.

The Role of Organic Materials in OLED Technology

Types of Organic Materials in OLEDs

Organic materials are the heart of OLED technology, categorized into three main types:

Fluorescent Materials: First-generation materials with 25% internal quantum efficiency. Used in low-cost applications like signage.

Phosphorescent Materials: Second-generation materials using heavy metals (e.g., iridium) to achieve 100% efficiency. Ideal for high-end displays like smartphones and TVs.

TADF (Thermally Activated Delayed Fluorescence) Materials: Emerging third-generation materials that bridge the gap between fluorescent and phosphorescent technologies without requiring heavy metals.

Organic Materials in Brownopto OLED

Brownopto specializes in optimizing phosphorescent materials for OLED displays. Their PHOLED technology reduces energy loss by converting both singlet and triplet excitons into light, enabling brighter screens with lower power consumption. This innovation is critical for applications like automotive dashboards and medical imaging, where high brightness and energy efficiency are essential.

Challenges in Organic Material Development

Despite progress, organic materials face challenges such as:

Blue Light Degradation: Blue OLEDs degrade faster than red/green ones. Brownopto addresses this with advanced phosphorescent blue emitters and encapsulation techniques.

Manufacturing Scalability: Vacuum deposition methods are costly for large panels. Brownopto is exploring inkjet printing to reduce production costs.

Advantages of OLED Displays

Superior Image Quality

OLED Display technology offers unparalleled image quality with:

True Black Levels: Individual pixel control enables perfect black and infinite contrast ratios.

Wide Color Gamut: Covers 100% DCI-P3 for vibrant, accurate colors in TVs and monitors.

Fast Response Times: Sub-millisecond response rates eliminate motion blur in gaming and video.

Design Flexibility

OLED’s self-emissive nature allows for:

Flexible and Foldable Displays: Used in devices like Samsung’s Galaxy Z Fold series.

Transparent Displays: Applied in AR glasses and smart windows.

Ultra-Thin Profiles: Enables lightweight, space-saving designs for smartphones and wearables.

Energy Efficiency

OLED Display technology consumes less power than LCDs, especially in dark scenes. Brownopto OLED panels further optimize energy use through:

Low-voltage operation for mobile devices.

Dynamic pixel dimming to reduce power in inactive areas.

Applications of OLED Display Technology

Consumer Electronics

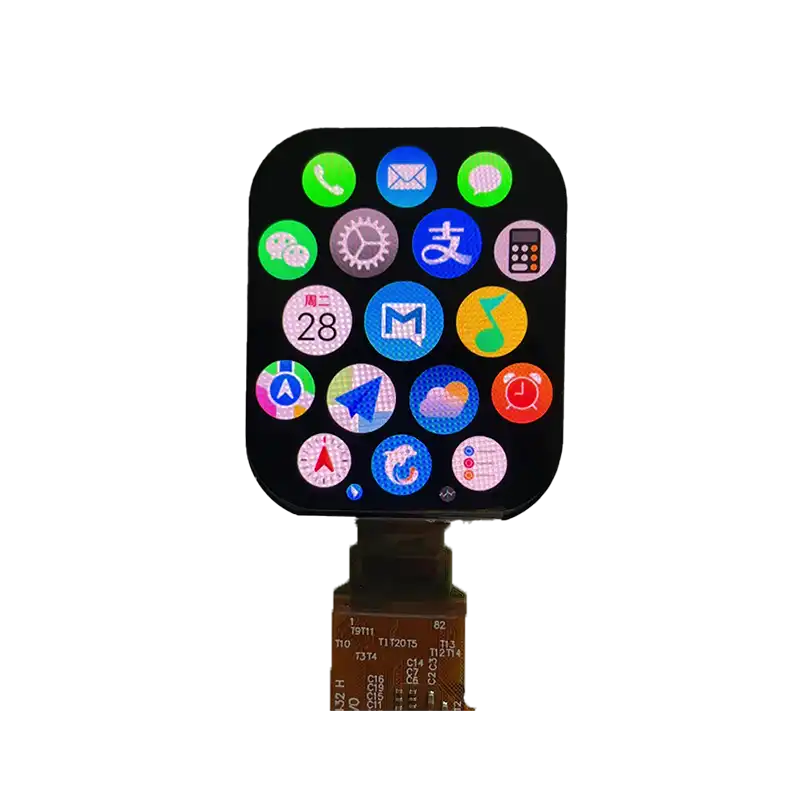

OLED Display technology dominates premium smartphones (e.g., iPhone Pro models) and TVs (e.g., LG Signature OLED). Brownopto OLED panels are used in devices requiring high durability and color accuracy, such as:

Smartphones with always-on displays.

4K/8K TVs with HDR support.

High-end laptops with curved screens.

Automotive and Industrial

OLED’s adaptability makes it ideal for automotive and industrial applications:

Curved Dashboards: BMW and Mercedes-Benz use OLED for adaptive lighting and navigation HUDs.

Medical Imaging: Philips’ OLED monitors provide high-contrast visuals for radiologists.

Industrial Control Panels: Durable, readable displays for factory automation.

Emerging Uses

Future applications of OLED Display technology include:

Wearable Health Monitors: Stretchable OLED patches for real-time biometric tracking.

Smart Packaging: Printed OLED labels for product authentication and freshness tracking.

Architectural Lighting: Modular OLED panels for dynamic building facades.

Challenges and Innovations in OLED Technology

Technical Limitations

OLED Display technology faces hurdles such as:

Lifetime Degradation: Blue OLEDs degrade faster. Brownopto mitigates this with improved phosphorescent materials.

Cost of Production: Vacuum deposition is expensive for large panels. Inkjet printing is a promising alternative.

Environmental Stability: Moisture and UV exposure require advanced encapsulation. Brownopto’s barrier films achieve<10-6 g/m²/day water vapor transmission.

Industry Solutions

Companies are addressing these challenges through:

COE (Color on Encapsulation) Technology: Reduces screen thickness and improves brightness by eliminating polarizing filters.

Graphene Cooling Layers: Enhances thermal management in flexible OLEDs.

Biodegradable Materials: Eco-friendly alternatives to address e-waste concerns.

Future Trends in OLED Displays

Next-Generation OLED Technologies

Emerging innovations in OLED Display technology include:

Quantum Dot OLED (QD-OLED): Combines quantum dots with self-emission for higher brightness and efficiency.

Stretchable OLEDs: Elastomeric substrates for wearable health monitors and haptic feedback devices.

Printed OLEDs: Low-cost, large-area displays for signage and smart packaging.

Brownopto’s Vision for the Future

Brownopto is leading the charge in next-generation OLED innovations, including:

Developing TADF materials for cost-effective, high-efficiency displays.

Exploring biodegradable OLEDs to reduce environmental impact.

Partnering with automotive and healthcare firms to integrate OLED into smart systems.

Market Growth Projections

According to TrendForce, OLED Display market growth will reach 80.6% in 2025, with applications expanding into:

Rollable TVs and foldable smartphones.

Transparent retail kiosks and smart windows.

Medical diagnostic tools with ultra-high contrast.

Conclusion: The Future of Brownopto OLED and OLED Display Innovation

OLED Display technology, powered by innovations like Brownopto OLED, is reshaping the digital landscape. From smartphones to automotive dashboards, OLED’s self-emissive properties offer unmatched image quality, design flexibility, and energy efficiency. While challenges like lifetime degradation and manufacturing costs remain, advancements in organic materials and production techniques are accelerating adoption.

As companies like Brownopto continue to push the boundaries of OLED technology, the future promises even more transformative applications. Whether it’s stretchable health monitors, printed smart labels, or biodegradable displays, OLED will remain a cornerstone of innovation for decades to come. For businesses seeking cutting-edge solutions, partnering with leaders in OLED Display technology can unlock new opportunities in design, performance, and sustainability.

Contact us to explore how Brownopto OLED and OLED Display solutions can elevate your products and services.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Recommended products

-

2.06-inch OLED Display | 410×502 Resolution | 600 Nits | SPI Screen

The 2.06-inch AMOLED display module is designed specifically for harsh industrial environments, feat

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Product Specifications: BRO601001ADisplayMode: AMOLED Screen Size (inch): 6.01 Resolution: 1080x2

-

6.39 INCH Outdoor AMOLED, 1080x2340, HD, High Brightness

Product Specifications: BRO639001AResolution: 1080x2340Voltage: 2.8VSize: 6.39 inchesDriver IC: SD52

-

4.39 INCH OLED display module I2C Interface 568×1210 Resolution

The 4.39-inch AMOLED display module (model BR439102-A1) introduced by (Shenzhen Brownopto Technology

-

1.38 INCH AMOLED Type 128x400 Low Power Wearable Display

Shenzhen Brownopto 1.38-inch AMOLED module: 128×400 resolution, 600-nit brightness, MIPI/QSPI/SPI in

-

1.93 INCH OLED Panel I2C 368x448 Industrial-Grade Panel

Shenzhen Brownopto Technology’s 1.93-inch AMOLED module (Model BR193103-A1) features a core advantag

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Product Specifications: BRO548001AResolution: 1080x1920Operating Voltage Range: 2.8VScreen Size: 5.4