Organic Light-Emitting Diode (OLED) displays have emerged as a game-changer in the world of visual technology. Unlike traditional Liquid Crystal Displays (LCDs), OLEDs rely on organic compounds that emit light when an electric current is applied. This innovation has enabled thinner, lighter, and more flexible screens, transforming industries from smartphones to automotive design. In this article, we delve into the working principles, advantages, applications, and future potential of OLED displays.

Why OLED Displays Outshine Traditional Technologies

OLED displays have rapidly replaced LCDs in many high-end devices due to their superior performance. Here’s why:

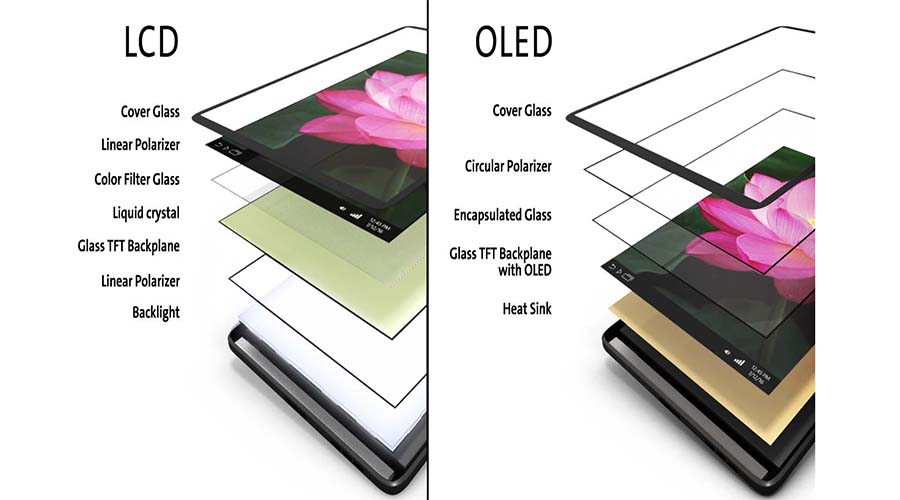

Self-Emitting Light: Each pixel in an OLED display generates its own light, eliminating the need for a backlight. This results in true black levels, higher contrast ratios, and deeper color accuracy.

Flexibility: OLED panels can be curved, bent, or even folded, enabling unique form factors like rollable TVs and wearable devices.

Energy Efficiency: OLEDs consume less power, especially when displaying dark scenes, making them ideal for battery-powered devices like smartphones and tablets.

Thin and Lightweight: With layers as thin as a few micrometers, OLEDs allow for ultra-slim devices and installations.

For example, the latest flagship smartphones use OLED screens to deliver vibrant colors and immersive visuals, while automotive manufacturers integrate curved OLED dashboards for a futuristic aesthetic. These advantages position OLEDs as the next-generation display solution.

How OLED Displays Work

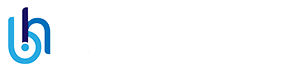

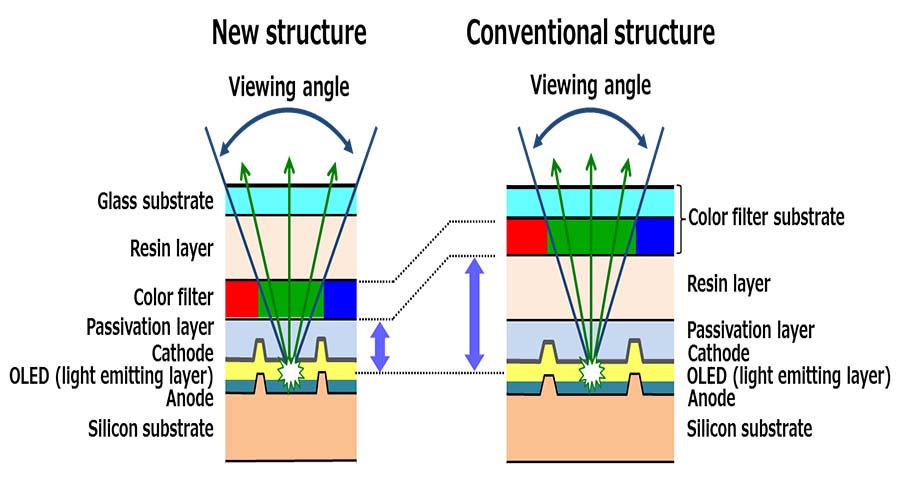

OLED technology relies on organic materials sandwiched between two electrodes. When an electric current passes through the organic layer, it emits light via electroluminescence. Key components include:

Anode: Removes electrons (holes) from the organic layer.

Cathode: Supplies electrons to the organic layer.

Organic Emissive Layer: Composed of light-emitting materials like poly(p-phenylene vinylene) (PPV) or phosphorescent compounds.

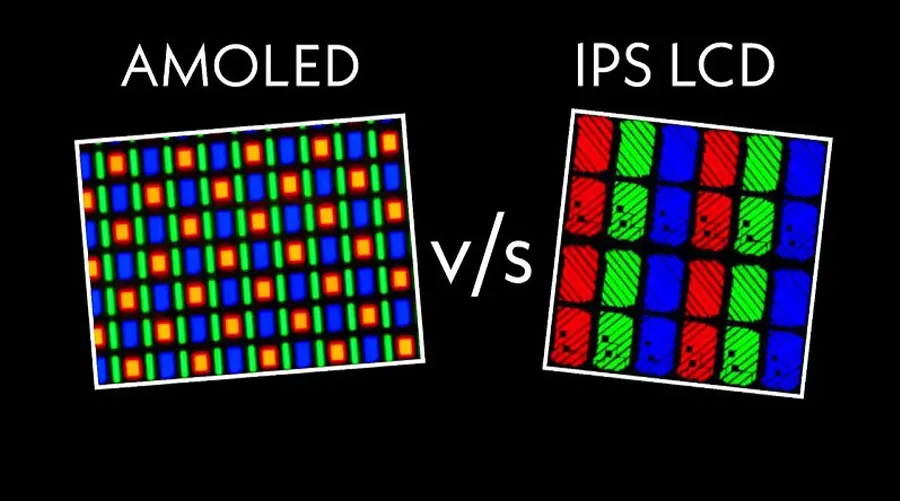

The color of the emitted light depends on the type of organic material used. Red, green, and blue subpixels combine to create a full-color display. Unlike LCDs, which require a separate backlight and color filters, OLEDs produce light directly, reducing complexity and improving efficiency.

Applications Across Industries

OLED displays are revolutionizing multiple sectors due to their versatility and performance:

Consumer Electronics: Smartphones, tablets, and TVs benefit from OLED’s vibrant colors and energy efficiency. Examples include foldable phones with flexible OLED screens.

Automotive: Curved OLED dashboards and head-up displays (HUDs) enhance driver visibility and safety. Luxury car brands use OLEDs for ambient lighting and infotainment systems.

Healthcare: Medical devices utilize OLEDs for high-contrast, glare-free displays in diagnostic imaging and surgical tools.

Retail and Advertising: Transparent OLED screens in stores create interactive product displays, while digital signage attracts customer attention with dynamic content.

Wearables: Smartwatches and AR glasses leverage OLEDs’ thin profile and low power consumption for compact, high-resolution interfaces.

A notable case study is a leading smartphone brand that adopted flexible OLEDs for its foldable device, achieving a 30% reduction in device thickness while doubling the screen size. Similarly, a luxury car manufacturer integrated curved OLED panels into its dashboard, improving ergonomics and aesthetics.

Manufacturing and Material Challenges

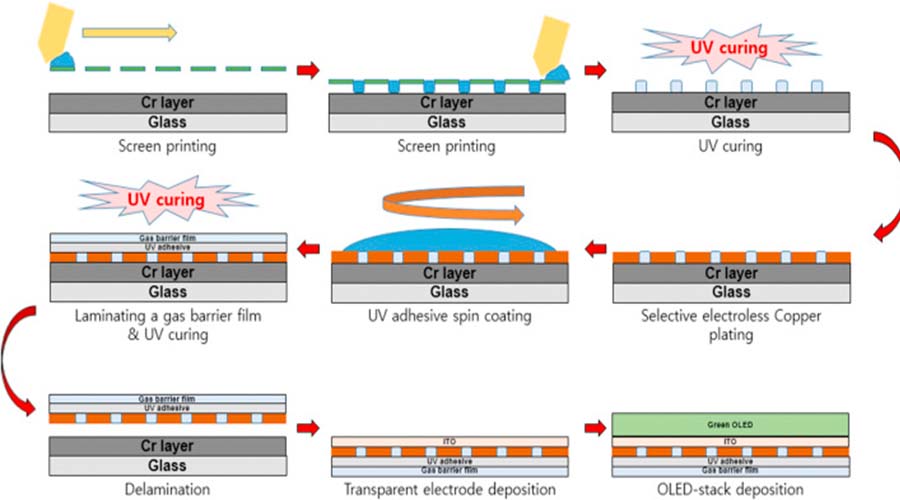

Producing OLED displays involves complex processes and specialized materials. Key steps include:

Vacuum Deposition: Organic materials are deposited in a vacuum chamber to form precise layers.

Encapsulation: To protect sensitive organic compounds from moisture and oxygen, thin-film encapsulation (TFE) is applied.

Substrate Preparation: Flexible OLEDs use plastic substrates, while rigid panels rely on glass. Advances in substrate technology enable bendable and rollable designs.

Challenges include material stability under heat and humidity, as well as scaling production for large-area displays. Researchers are exploring alternatives like carbon-based organic materials and laser patterning to improve yield and reduce costs.

Future Innovations in OLED Technology

The evolution of OLED displays is driven by advancements in materials, manufacturing, and integration with emerging technologies. Key trends include:

Micro OLED: Miniaturized OLEDs for augmented reality (AR) and virtual reality (VR) headsets, offering ultra-high resolution and low latency.

Transparent and Holographic Displays: Transparent OLEDs enable see-through screens for smart windows, while holographic OLEDs create 3D visualizations.

Printed OLEDs: Inkjet printing of organic materials reduces production costs and enables scalable manufacturing for large-format displays.

Flexible and Stretchable Designs: OLEDs that can conform to irregular surfaces, such as wearable fitness trackers or smart clothing.

Sustainable Materials: Biodegradable organic compounds and recycling-friendly substrates to reduce environmental impact.

By 2030, experts predict that OLEDs will dominate the premium TV and smartphone markets, with over 50% of new devices incorporating flexible or transparent OLED screens. Innovations like rollable TVs and foldable laptops will redefine user interactions with technology.

Conclusion and Industry Impact

OLED displays represent a paradigm shift in visual technology, combining superior image quality, flexibility, and energy efficiency. Their adoption across industries—from consumer electronics to healthcare and automotive—demonstrates their transformative potential. As manufacturing processes improve and costs decline, OLEDs will become even more accessible, driving innovation in product design and user experiences.

For businesses and developers, investing in OLED technology is not just about staying competitive—it’s about shaping the future of how we interact with digital content. Whether you’re designing the next generation of wearable devices or reimagining automotive interiors, OLED displays offer endless possibilities.

Ready to explore OLED solutions for your project? Contact us today to discuss customized OLED display options tailored to your needs.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Recommended products

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Product Specifications: BRO392001AResolution: 1080x1024Operating Voltage Range: 28VScreen Size: 3.92

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Product Specifications: BRO601001ADisplayMode: AMOLED Screen Size (inch): 6.01 Resolution: 1080x2

-

6.39 INCH Outdoor AMOLED, 1080x2340, HD, High Brightness

Product Specifications: BRO639001AResolution: 1080x2340Voltage: 2.8VSize: 6.39 inchesDriver IC: SD52

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Product Specifications: BRO548001AResolution: 1080x1920Operating Voltage Range: 2.8VScreen Size: 5.4