What Is an OLED Display?

AnOLED Display, or Organic Light Emitting Diode Display, is an advanced visualization technology that uses organic compounds to emit light when an electrical current is applied. Unlike traditional LCDs (Liquid Crystal Displays) that require backlighting, OLED Displays are self-emissive, enabling thinner, lighter, and more energy-efficient screens.

The term “OLED Display” represents a significant leap in display technology that offers unparalleled contrast, higher color accuracy, and deeper blacks. These displays are widely used in consumer electronics, medical devices, automotive dashboards, and industrial equipment.

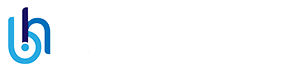

Basic Structure of an OLED Display

The typical OLED Display consists of several thin organic layers sandwiched between two electrodes on a substrate. When voltage passes through, the organic layers emit light by recombination of electrons and holes. The main layers include anode, cathode, emissive layer, and conductive layer. This layered construction supports flexible and lightweight designs.

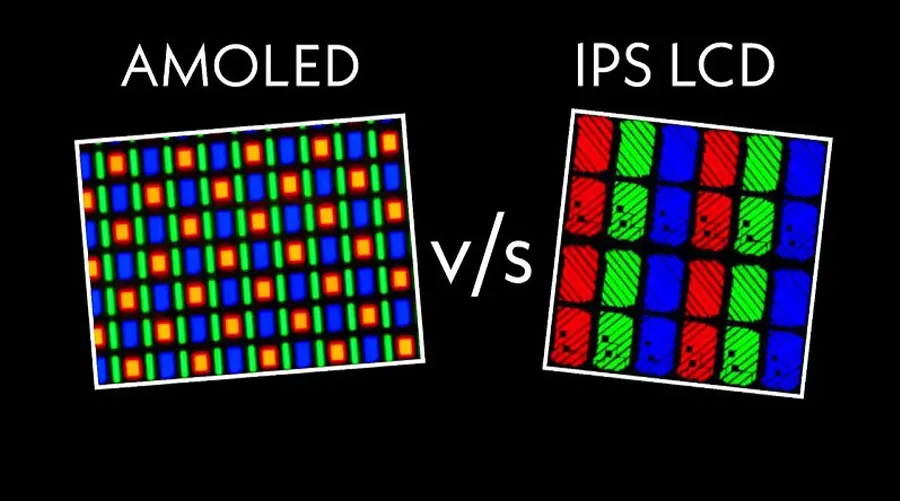

OLED Display vs Other Display Technologies

Compared to LCDs and other technologies like MicroLED, OLED Displays provide superior image quality due to self-lit pixels that do not require backlight, offering better viewing angles, higher contrast ratios, and faster response times. Additionally, OLED Display can be fabricated on flexible substrates, allowing curved and foldable screens.

In-Depth OLED Display Technology

Fundamental Principles of OLED Display Technology

The key to OLED Display technology lies in utilizing organic electroluminescent materials that emit light electrical stimulation. Applying current causes electrons to move across organic layers and recombine, releasing photons of light. Since each pixel emits its own light, the OLED Display eliminates the need for bulky backlights, resulting in slimmer displays.

Material engineering plays a critical role in performance and lifespan of OLED Displays. Common materials include small molecules and polymers, and multiple organic layers optimize charge balance and light emission.

Active-Matrix and Passive-Matrix OLED Displays

OLED Displays come in two categories: Active-Matrix OLED (AMOLED) and Passive-Matrix OLED (PMOLED). AMOLED uses thin-film transistor (TFT) arrays to activate individual pixels, supporting high resolution and fast refresh rates for smartphones and large displays. PMOLED is simpler, suitable for smaller, low-resolution screens, often used in wearable devices and secondary displays.

Manufacturing Process of OLED Display

The production of a reliable OLED Display involves substrate preparation, vacuum deposition of organic layers, encapsulation to prevent moisture ingress, and rigorous testing. Technologies such as thermal evaporation and inkjet printing are utilized for layer deposition.

Key Advantages of OLED Display

Exceptional Contrast and Image Quality of OLED Display

The self-emissive nature of pixels in OLED Displays produces absolute black levels by switching off pixels completely. This leads to an infinite contrast ratio and richer colors, which are critical for medical imaging, professional photography, and automotive dashboard displays.

Energy Efficiency Benefits of OLED Display

OLED Displays consume significantly less power than LCDs, especially when displaying darker images or user interfaces. This efficiency results from the lack of a power-hungry backlight and direct pixel-level control of light emission, improving battery life in smartphones, wearables, and IoT devices.

Thin, Lightweight, and Flexible OLED Displays

With a thickness often below 1.5mm, OLED Displays offer unparalleled design flexibility including curved, foldable, and even rollable displays. Their lightweight nature benefits portable applications where size and weight are critical constraints.

Durability and Industrial-Grade OLED Displays

Industrial-grade OLED Displays withstand extreme temperature ranges (from -30°C up to 80°C) and maintain a lifespan of over 50,000 hours. This makes them ideal for demanding environments such as automotive instrument clusters and factory automation equipment.

NangungunaOLED DisplayMga Application sa Buong Industriya

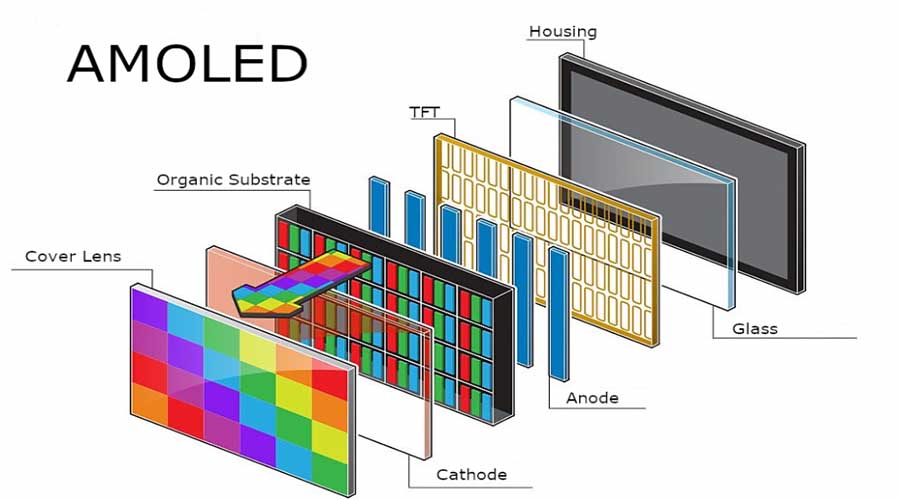

Medical Equipment Using OLED Display Technology

Precise and vibrant OLED Displays enhance diagnostic equipment, surgical monitors, and patient interface devices with high resolution and accurate color reproduction, improving medical outcomes and operational safety.

Automotive Dashboard and Infotainment OLED Displays

Modern vehicles increasingly employ curved and futuristic OLED Displays for instrument clusters and in-dash entertainment systems. Their durability ensures readability under varying light conditions and operational stress.

Smart IoT and Wearables Equipped with OLED Display

Wearables such as smartwatches and fitness trackers benefit from the compactness and low power consumption of OLED Displays, providing crystal-clear feedback and longer battery life for users on the go.

Industrial Automation and Equipment Featuring OLED Display

Industrial control panels and diagnostic interfaces implement OLED Display modules for robust operation in harsh environments, delivering reliable, easy-to-read data streams essential for production efficiency.

OLED Display Customization & Buying Guide

Choosing the Right OLED Display for Your Project

Upang piliin ang pinakamainamOLED Display, isaalang-alang ang mga kritikal na parameter gaya ng resolution, mga dimensyon, pagiging tugma ng interface (SPI, I2C, atbp.), liwanag, at mga kondisyon sa pagpapatakbo sa kapaligiran. Tinitiyak ng pagtukoy sa mga kinakailangan na partikular sa application ang pagganap at tagumpay ng pagsasama.

Pagtitiyak ng Interface at Komunikasyon Compatibility saOLED Displays

I-verify na napili moOLED Displaysumusuporta sa mga kinakailangang protocol ng komunikasyon tulad ng SPI at I2C, na nag-streamline ng pagsasama ng controller at katatagan ng system para sa mga naka-embed na proyekto.

Mga Sertipikasyon at Pamantayan sa Kalidad para saOLED Displays

Mag-opt para saOLED Displaymga module na na-certify sa mga internasyonal na pamantayan tulad ng RoHS, CE, at ISO. Ginagarantiyahan ng mga certification na ito ang pagsunod sa kapaligiran, kaligtasan, at pagiging maaasahan ng produkto sa mga pandaigdigang merkado.

Suporta at Rapid Prototyping para saOLED Displays

Isang pinagkakatiwalaanOLED Displaynag-aalok ang provider ng teknikal na suporta, mga mapagkukunan ng firmware/driver, at mabilis na mga serbisyo ng prototyping upang mapabilis ang iyong oras sa merkado at mabawasan ang mga panganib sa pag-unlad.

Emerging OLED Display Market Trends

Trajectory ng Paglago ng PandaigdigOLED Displaypalengke

Ang globalOLED DisplayAng merkado ay patuloy na mabilis na lumalawak, pinalakas ng tumataas na pag-aampon ng smartphone, paglaki ng mga naisusuot na device, at pagtaas ng demand sa automotive electronics. Hinuhulaan ng mga analyst ang taunang rate ng paglago na hihigit sa 20% sa susunod na limang taon.

Flexibility at Innovation DrivingOLED DisplayPag-ampon

Flexible at natitiklopOLED Displaysay muling hinuhubog ang mga paradigma sa disenyo ng device, na nagpapagana ng mga bagong form factor at karanasan ng user sa consumer electronics at automotive interiors.

Mga Pagsisikap sa Pagbawas ng Gastos at Pagiging Madaling Magamit sa Industriya

Ang mga pag-unlad sa mga teknolohiya sa pagmamanupaktura at economies of scale ay nagpapababa sa mga gastos ngOLED Displays, pagpapalawak ng kanilang abot sa mga mid-range na produkto at bagong mga segment ng merkado.

Technological Convergence at Future Prospects para saOLED Display

Ang mga integrasyon sa MicroOLED, transparent OLED, at AMOLED/PMOLED hybrids ay nagtutulak pa ng mga kakayahan sa pagpapakita, lalo na para sa augmented reality (AR) at virtual reality (VR) na mga device na nangangailangan ng mataas na pixel density at mababang latency.

Conclusion: The Future of OLED Display

Ang komprehensibong gabay na ito ay ginalugad ang mga pangunahing kaalaman, benepisyo, aplikasyon sa industriya, at pananaw sa merkado ngOLED Displayteknolohiya. Ang kumbinasyon ng mga superyor na contrast ratio, manipis na flexible form factor, at energy efficiency ay nagpapalakasOLED Displaysnangunguna sa display innovation.

Habang tumatanda ang teknolohiya at pagmamanupaktura, inaasahan naminOLED Displaysupang maging pamantayan sa medikal, automotive, IoT, at mga pang-industriyang aplikasyon. Dapat isaalang-alang ng mga kumpanyang naglalayon para sa mapagkumpitensyang kalamangan ang pamumuhunan sa nako-customize, na-certifyOLED Displaymga solusyon upang mapakinabangan ang kalakaran na ito.

Sa Brownopto, dalubhasa kami sa paghahatid ng mataas na kalidad, nako-customizeOLED Displaymga module na may komprehensibong teknikal na suporta at pandaigdigang sertipikasyon upang matugunan ang mga umuusbong na pangangailangan ng magkakaibang industriya sa buong mundo.

Mga pinakabagong artikulo

-

Bakit 1–2" na AMOLED ang Susi sa AR/XR sa 2025

Bakit Nagiging Mahalaga ang 1–2 Inch AMOLED Display sa AR/XR Boom (2025 Industry Insight) body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Mga Stretched Bar LCD Display para sa Retail: Palakasin ang Benta at Pakikipag-ugnayan sa Mga Supermarket

Tuklasin kung paano pinahusay ng mga stretched bar LCD display ang shelf-edge marketing ng supermarket, humimok ng mga benta, at bawasan

-

Naka-stretch na LCD Solutions para sa Mga Restaurant at Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Inirerekomendang mga produkto

-

2.1 pulgada 410×502 AMOLED E-Paper Display Module para sa Handheld Scanner

Ang 2.1 pulgadang OLED display module ay isang compact, high-resolution na solusyon na idinisenyo para sa integration int

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Mga Detalye ng Produkto: BRO392001AResolution: 1080x1024Sinakop ng Operating Voltage: 28VSLaki ng Screen: 3.92

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Mga Detalye ng Produkto: BRO601001ADiplayMode: AMOLED na Laki ng Screen (pulgada): 6.01 Resolution: 1080x2

-

1.93 INCH OLED Panel I2C 368x448 Industrial-Grade Panel

Nagtatampok ang 1.93-pulgadang AMOLED module ng Shenzhen Brownopto Technology (Model BR193103-A1) ng isang pangunahing advantage

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Mga Detalye ng Produkto: BRO548001AResolution: 1080x1920Sinakop ng Operating Voltage: 2.8VSLaki ng Screen: 5.4