What Is an Layar OLED?

SebuahLayar OLED, or Organic Light Emitting Diode Display, is an advanced visualization technology that uses organic compounds to emit light when an electrical current is applied. Unlike traditional LCDs (Liquid Crystal Displays) that require backlighting, OLED Displays are self-emissive, enabling thinner, lighter, and more energy-efficient screens.

The term “Layar OLED” represents a significant leap in display technology that offers unparalleled contrast, higher color accuracy, and deeper blacks. These displays are widely used in consumer electronics, medical devices, automotive dashboards, and industrial equipment.

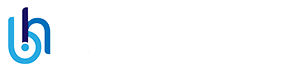

Basic Structure of an Layar OLED

The typical Layar OLED consists of several thin organic layers sandwiched between two electrodes on a substrate. When voltage passes through, the organic layers emit light by recombination of electrons and holes. The main layers include anode, cathode, emissive layer, and conductive layer. This layered construction supports flexible and lightweight designs.

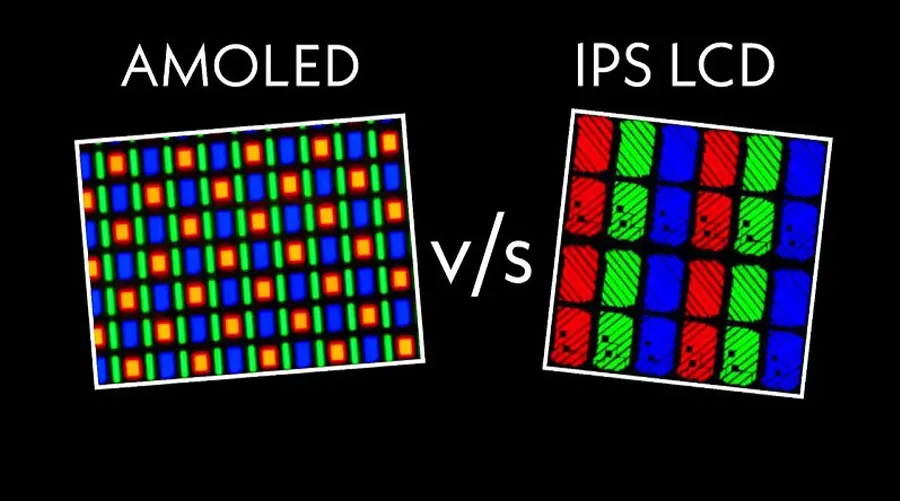

Layar OLED vs Other Display Technologies

Compared to LCDs and other technologies like MicroLED, OLED Displays provide superior image quality due to self-lit pixels that do not require backlight, offering better viewing angles, higher contrast ratios, and faster response times. Additionally, Layar OLED can be fabricated on flexible substrates, allowing curved and foldable screens.

In-Depth Layar OLED Technology

Fundamental Principles of Layar OLED Technology

The key to Layar OLED technology lies in utilizing organic electroluminescent materials that emit light electrical stimulation. Applying current causes electrons to move across organic layers and recombine, releasing photons of light. Since each pixel emits its own light, the Layar OLED eliminates the need for bulky backlights, resulting in slimmer displays.

Material engineering plays a critical role in performance and lifespan of OLED Displays. Common materials include small molecules and polymers, and multiple organic layers optimize charge balance and light emission.

Active-Matrix and Passive-Matrix OLED Displays

OLED Displays come in two categories: Active-Matrix OLED (AMOLED) and Passive-Matrix OLED (PMOLED). AMOLED uses thin-film transistor (TFT) arrays to activate individual pixels, supporting high resolution and fast refresh rates for smartphones and large displays. PMOLED is simpler, suitable for smaller, low-resolution screens, often used in wearable devices and secondary displays.

Manufacturing Process of Layar OLED

The production of a reliable Layar OLED involves substrate preparation, vacuum deposition of organic layers, encapsulation to prevent moisture ingress, and rigorous testing. Technologies such as thermal evaporation and inkjet printing are utilized for layer deposition.

Key Advantages of Layar OLED

Exceptional Contrast and Image Quality of Layar OLED

The self-emissive nature of pixels in OLED Displays produces absolute black levels by switching off pixels completely. This leads to an infinite contrast ratio and richer colors, which are critical for medical imaging, professional photography, and automotive dashboard displays.

Energy Efficiency Benefits of Layar OLED

OLED Displays consume significantly less power than LCDs, especially when displaying darker images or user interfaces. This efficiency results from the lack of a power-hungry backlight and direct pixel-level control of light emission, improving battery life in smartphones, wearables, and IoT devices.

Thin, Lightweight, and Flexible OLED Displays

With a thickness often below 1.5mm, OLED Displays offer unparalleled design flexibility including curved, foldable, and even rollable displays. Their lightweight nature benefits portable applications where size and weight are critical constraints.

Durability and Industrial-Grade OLED Displays

Industrial-grade OLED Displays withstand extreme temperature ranges (from -30°C up to 80°C) and maintain a lifespan of over 50,000 hours. This makes them ideal for demanding environments such as automotive instrument clusters and factory automation equipment.

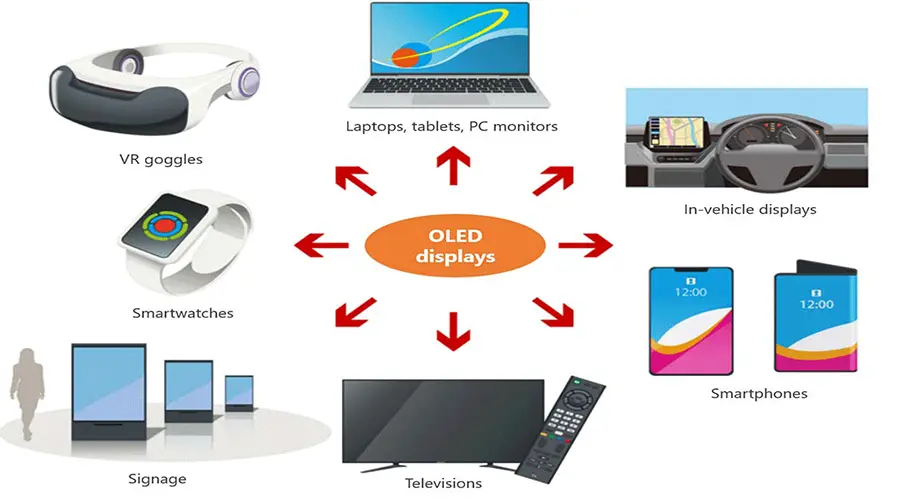

AtasLayar OLEDAplikasi di Berbagai Industri

Medical Equipment Using Layar OLED Technology

Precise and vibrant OLED Displays enhance diagnostic equipment, surgical monitors, and patient interface devices with high resolution and accurate color reproduction, improving medical outcomes and operational safety.

Automotive Dashboard and Infotainment OLED Displays

Modern vehicles increasingly employ curved and futuristic OLED Displays for instrument clusters and in-dash entertainment systems. Their durability ensures readability under varying light conditions and operational stress.

Smart IoT and Wearables Equipped with Layar OLED

Wearables such as smartwatches and fitness trackers benefit from the compactness and low power consumption of OLED Displays, providing crystal-clear feedback and longer battery life for users on the go.

Industrial Automation and Equipment Featuring Layar OLED

Industrial control panels and diagnostic interfaces implement Layar OLED modules for robust operation in harsh environments, delivering reliable, easy-to-read data streams essential for production efficiency.

Layar OLED Customization & Buying Guide

Choosing the Right Layar OLED for Your Project

To select the optimal Layar OLED, consider critical parameters such as resolution, dimensions, interface compatibility (SPI, I2C, etc.), brightness, and environmental operating conditions. Defining application-specific requirements ensures performance and integration success.

Ensuring Interface and Communication Compatibility with OLED Displays

Verifikasi bahwa pilihan AndaLayar OLEDmendukung protokol komunikasi yang diperlukan seperti SPI dan I2C, yang menyederhanakan integrasi pengontrol dan stabilitas sistem untuk proyek tertanam.

Sertifikasi dan Standar Mutu untukOLED Displays

Pilih untukLayar OLEDModul-modul ini telah disertifikasi sesuai standar internasional seperti RoHS, CE, dan ISO. Sertifikasi ini menjamin kepatuhan lingkungan, keamanan, dan keandalan produk di seluruh pasar global.

Dukungan dan Prototipe Cepat untukOLED Displays

Yang terpercayaLayar OLEDPenyedia menawarkan dukungan teknis, sumber daya firmware/driver, dan layanan pembuatan prototipe cepat untuk mempercepat waktu Anda untuk memasarkan dan mengurangi risiko pengembangan.

Emerging Layar OLED Market Trends

Lintasan Pertumbuhan Ekonomi GlobalLayar OLEDPasar

DuniaLayar OLEDPasar terus berkembang pesat, didorong oleh meningkatnya adopsi ponsel pintar, pertumbuhan perangkat yang dapat dikenakan (wearable), dan meningkatnya permintaan elektronik otomotif. Analis memperkirakan tingkat pertumbuhan tahunan akan melampaui 20% selama lima tahun ke depan.

Fleksibilitas dan Inovasi MengemudiLayar OLEDAdopsi

Fleksibel dan dapat dilipatOLED Displaysmembentuk kembali paradigma desain perangkat, memungkinkan faktor bentuk dan pengalaman pengguna baru dalam elektronik konsumen dan interior otomotif.

Upaya Pengurangan Biaya dan Aksesibilitas Industri

Kemajuan dalam teknologi manufaktur dan skala ekonomi mendorong penurunan biayaOLED Displays, memperluas jangkauan mereka ke produk kelas menengah dan segmen pasar baru.

Konvergensi Teknologi dan Prospek Masa Depan untukLayar OLED

Integrasi dengan MicroOLED, OLED transparan, dan hibrida AMOLED/PMOLED mendorong kemampuan tampilan lebih jauh, khususnya untuk perangkat realitas tertambah (AR) dan realitas virtual (VR) yang menuntut kepadatan piksel tinggi dan latensi rendah.

Conclusion: The Future of Layar OLED

Panduan komprehensif ini telah mengeksplorasi fundamental, manfaat, aplikasi industri, dan prospek pasarLayar OLEDteknologi. Kombinasi rasio kontras yang unggul, faktor bentuk yang tipis dan fleksibel, dan efisiensi energi mendorongOLED Displayske garis depan inovasi tampilan.

Seiring dengan semakin matangnya teknologi dan manufaktur, kami berharapOLED Displaysuntuk menjadi standar dalam aplikasi medis, otomotif, IoT, dan industri. Perusahaan yang ingin meraih keunggulan kompetitif sebaiknya mempertimbangkan untuk berinvestasi dalam produk yang dapat disesuaikan dan tersertifikasi.Layar OLEDsolusi untuk memanfaatkan tren ini.

Di Brownopto, kami mengkhususkan diri dalam memberikan produk berkualitas tinggi dan dapat disesuaikanLayar OLEDmodul dengan dukungan teknis komprehensif dan sertifikasi global untuk memenuhi kebutuhan industri yang terus berkembang di seluruh dunia.

Latest articles

-

Mengapa AMOLED 1–2" adalah Kunci AR/XR di Tahun 2025

Mengapa Layar AMOLED 1–2 Inci Menjadi Penting dalam Booming AR/XR (Wawasan Industri 2025)

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Temukan bagaimana tampilan LCD batang yang diregangkan meningkatkan pemasaran di tepi rak supermarket, mendorong penjualan, dan mengurangi

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

LCD yang direntangkan menawarkan tampilan ramping dan kecerahan tinggi yang cocok untuk menu restoran dan layanan perhotelan.

Produk yang direkomendasikan

-

Modul Layar E-Paper AMOLED 2,1 inci 410×502 untuk Pemindai Genggam

Modul tampilan OLED 2,1 inci adalah solusi resolusi tinggi yang ringkas yang dirancang untuk integrasi ke dalam

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Spesifikasi Produk: BRO392001AResolusi: 1080x1024Rentang Tegangan Operasi: 28VUkuran Layar: 3.92

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Spesifikasi Produk: BRO601001ADisplayMode: AMOLED Ukuran Layar (inci): 6.01 Resolusi: 1080x2

-

1.93 INCH OLED Panel I2C 368x448 Industrial-Grade Panel

Modul AMOLED 1,93 inci dari Shenzhen Brownopto Technology (Model BR193103-A1) memiliki keunggulan inti

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Spesifikasi Produk: BRO548001AResolusi: 1080x1920Rentang Tegangan Operasi: 2.8VUkuran Layar: 5.4