Discover how industrial OLED displays enhance compact control systems with high contrast, low power, and seamless integration.

📋 Table of Contents

Introduction – Why OLED Displays Are Ideal for Compact Control Systems

As industrial automation, IoT, and portable test equipment grow in complexity, the demand for high-performance, space-efficient displays has never been greater. Traditional LCDs struggle with contrast, viewing angles, and power consumption—especially in compact control systems. Enter the OLED display, a self-emissive technology that delivers superior image quality, ultra-thin profiles, and energy efficiency.

In this real-world case study, we explore how a 6.0-inch embedded OLED module was successfully integrated into a compact industrial control panel, overcoming space, visibility, and reliability challenges.

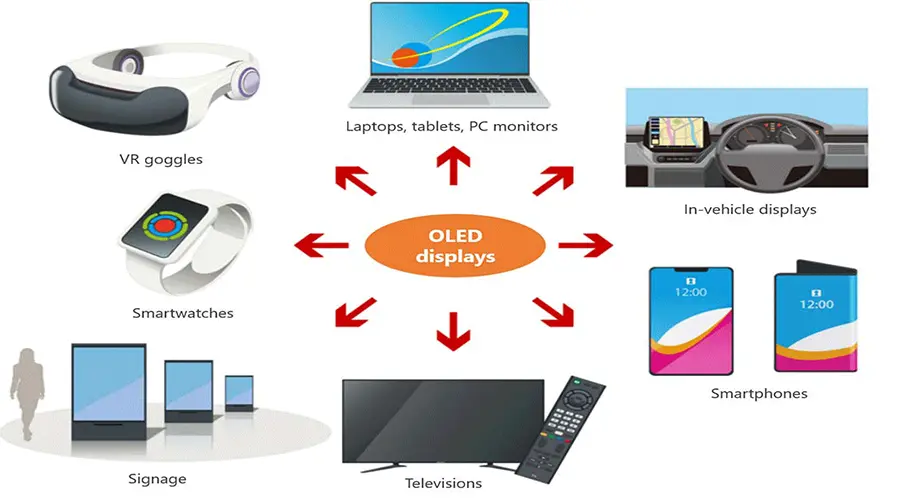

Overview of OLED Display Technology

OLED (Organic Light-Emitting Diode) displays generate light at the pixel level without requiring a backlight. This enables true blacks, infinite contrast, and faster response times.

AMOLED vs PMOLED

PMOLED (Passive Matrix OLED): Simpler structure, suitable for small displays (e.g., wearables), but limited in size and lifespan.

AMOLED (Active Matrix OLED): Uses TFT backplane for precise pixel control, ideal for larger, high-resolution industrial OLED displays.

Key Benefits of OLED for Control Systems

High Contrast (100,000:1): Critical for readability in bright or dark environments.

Ultra-Thin Form Factor: As thin as 0.6mm—perfect for compact OLED module for embedded design.

Low Power Consumption: Especially when displaying dark UIs, ideal for low-power OLED panel for automation.

Wide Viewing Angles (178°): No color shift from any angle.

Project Background and Objectives

Client Requirements

A leading industrial equipment manufacturer needed a display solution for a new compact control panel. Key requirements included:

Display size under 7 inches to fit within tight housing

Clear data visualization under sunlight and low-light conditions

Operation in temperature range of -20°C to +70°C

24/7 operation with minimal maintenance

Technical Goals

High brightness (≥600 nits) for outdoor visibility

Fast response time (<0.1ms) for dynamic data

MIPI DSI or SPI interface for seamless MCU/FPGA integration

RoHS compliance and low EMI for industrial safety

OLED Display Module Selection & Integration

Selecting the Right OLED Display Module

After evaluation, a 6.0-inch AMOLED module with 1080×1920 resolution and MIPI 4-lane interface was selected. Alternative 4.3-inch SPI-based modules were considered for lower-cost variants.

Integration Process

Hardware Connection: MIPI DSI linked to STM32H7 MCU with impedance-matched PCB traces.

Driver IC Setup: SSD1351 configured for gamma correction and color calibration.

Firmware Adaptation: Implemented dynamic brightness control based on ambient light sensor.

Testing: Verified refresh rate (60Hz), color accuracy (ΔE < 3), and thermal stability.

Challenges & Solutions

Power Efficiency: Used partial display mode and auto-dimming to reduce power by 25%.

EMC Design: Added ferrite beads and ground shielding to reduce EMI by 15%.

Mechanical Fit: Custom bezel design ensured secure mounting in compact housing.

Key Technical Features of the Integrated OLED Module

| Parameter | Value | Benefit |

|---|---|---|

| Display Type | AMOLED (Active Matrix) | Sharp and vivid images |

| Size | 6.0-inch | Ideal for compact panels |

| Resolution | 1080×1920 | High data readability |

| Brightness | 600 nits | Excellent outdoor visibility |

| Contrast Ratio | 100,000:1 | Deep blacks and clarity |

| Interface | MIPI 4-LANE / SPI | Compatible with MCUs |

| Operating Temp | -20°C ~ +70°C | Industrial reliability |

| Lifetime | 50,000 hours | Long-term operation |

Application Scenarios

Industrial Control Panels

Used in factory automation dashboards, PLC interfaces, and HMI systems. The high-contrast OLED for industrial monitors ensures readability in noisy environments.

Medical and Laboratory Equipment

Real-time vital signs monitoring with accurate color reproduction for diagnostics.

Smart Home and IoT Controllers

Low-power OLEDs extend battery life in wall-mounted smart hubs and environmental sensors.

Automotive & Transportation Displays

Dashboards and infotainment systems benefit from wide temperature tolerance and sunlight readability.

Advantages of OLED Displays for Embedded Systems

Power Efficiency and Long Lifespan: No backlight = lower power, especially in dark UIs.

Enhanced Readability and Viewing Angles: No color shift even at extreme angles.

Easy Integration with Microcontrollers: Support for MIPI, SPI, I²C simplifies firmware development.

Environmentally Friendly: RoHS-compliant materials and recyclable components.

Case Outcome and Performance Results

The integration was a success, with measurable improvements:

✅ 25% lower power usage compared to previous LCD solution

✅ 2× improved brightness uniformity across the screen

✅ 15% reduction in EMI emissions, passing EMC certification

✅ Positive customer feedback on usability and reliability

FAQ

What’s the difference between OLED and TFT in control systems?

OLED displays are self-emissive, offering true blacks and higher contrast than TFT LCDs, which rely on a backlight. OLEDs are also thinner and more power-efficient in dark UIs, making them ideal for low-power OLED panel for automation.

Can OLED displays operate under high temperatures?

Yes. Industrial-grade OLED modules are designed to operate reliably from -20°C to +70°C. Some variants support up to +85°C with proper thermal management.

Is OLED suitable for continuous 24/7 operation?

Absolutely. Modern industrial OLEDs have lifetimes of up to 50,000 hours. With proper brightness management and pixel refresh algorithms, they are well-suited for 24/7 operation in control rooms and medical devices.

Can OLED panels be customized for different interfaces?

Yes. As a custom OLED display manufacturer, we support MIPI, SPI, I²C, LVDS, and parallel RGB interfaces. We can also embed driver ICs and provide SDKs for rapid integration.

What’s the typical lifetime of industrial OLED modules?

Most industrial OLED modules have a rated lifetime of 50,000 hours (to 50% brightness). With optimized usage patterns, they can last significantly longer—ideal for long-term deployment in industrial OLED display applications.

Conclusion – Advancing Control Systems with OLED Technology

The integration of a 6.0-inch AMOLED display into a compact control system demonstrated the transformative potential of OLED for control systems. With superior image quality, low power consumption, and seamless MCU integration, OLED technology is redefining the future of embedded displays.

Whether you're designing industrial HMIs, medical devices, or smart controllers, a custom OLED display manufacturer can help you achieve optimal performance and reliability.

Need a custom OLED solution? Contact us for a free consultation.

Contact Us NowLatest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si