OLED (Organic Light-Emitting Diode) technology is revolutionizing traditional LCD/LED applications with its self-emissive pixels, ultra-high contrast, and flexible design. According to Omdia data, global OLED panel shipments grew by 23% in 2023, with the industrial, medical, and automotive sectors accounting for over 40%. This article explores the top 10 OLED display applications, provides technical insights, and offers selection guidelines aligned with E-E-A-T (Expertise, Authoritativeness, Trustworthiness) principles.

Introduction: Core Advantages of OLED Technology

OLED displays leverage self-emissive pixels and ultra-thin flexible designs to redefine high-end display standards. Key advantages include:

Ultra-High Contrast Ratio: 1,000,000:1 for optimal visibility in bright environments.

Low Power Consumption: Local dimming reduces power usage by 40%.

Wide Viewing Angles: 178° without color shift.

Medical Applications: Precision Color & Sterile Environment

Surgical Navigation Displays: 0.01% Color Accuracy Calibration

Core Requirement: Subtle tissue color differences (e.g., blood vessels, nerves) directly impact surgical success rates.

OLED Advantages:

100% DCI-P3 Color Coverage: Accurately reproduces biological tissue hues.

Antimicrobial Glass Encapsulation: IP65-rated for surgical room safety.

Test Data: A tier-3 hospital reported a 62% reduction in surgical errors with OLED compared to LCD.

Portable Diagnostic Devices: Low Power & High Brightness

Use Case: Handheld ultrasound machines and endoscope displays require 500cd/m² brightness at 0.1W power consumption.

Technical Solutions:

Local Dimming Technology: Powers only active regions.

Gorilla Glass Lamination: 1.5mm thickness with 3x drop resistance.

Industrial Automation: Extreme Environmental Reliability

Heavy-Industrial Control Panels: -30°C to 80°C Operating Range

Challenge: Traditional LCDs experience ghosting and lag in high-temperature environments like oil drilling and steel manufacturing.

OLED Solutions:

Rare Earth Metal Encapsulation: Blocks moisture and dust infiltration.

50,000-Hour Lifespan: Passes MIL-STD-810G thermal cycling tests.

Case Study: An oilfield HMI system saw a 57% reduction in downtime after switching to OLED.

Flexible Sensor Integration: Curved Screen Revolution

Innovative Applications:

Curved Industrial Control Consoles: Fits robotic arm contours with<5° deviation.

Pressure-Sensitive Integrated Displays: LG Display's flexible OLED supports 1,000+ touch points.

Supplier Requirements: Request fatigue test reports for bending radius ≤5mm.

Automotive Electronics: Safety & Aesthetic Evolution

Transparent OLED Dashboards: Real-Time Information & Real-World Fusion

Technical Breakthroughs:

1000cd/m² Peak Brightness: Maintains visibility in direct sunlight.

0.1ms Response Time: Eliminates motion blur (LCDs average 5ms).

Flagship Example: The 2024 Mercedes EQS "Hyperscreen" uses three seamless OLED panels.

Rearview Mirror Replacement: Ultra-Thin Lightweight Design

Key Specifications:

Thickness ≤2mm: Reduces weight by 60%, lowering wind resistance.

Anti-Glare Coating: Nighttime glare reduction by 80%.

Consumer Electronics: Foldable Phones & Lifespan Comparison

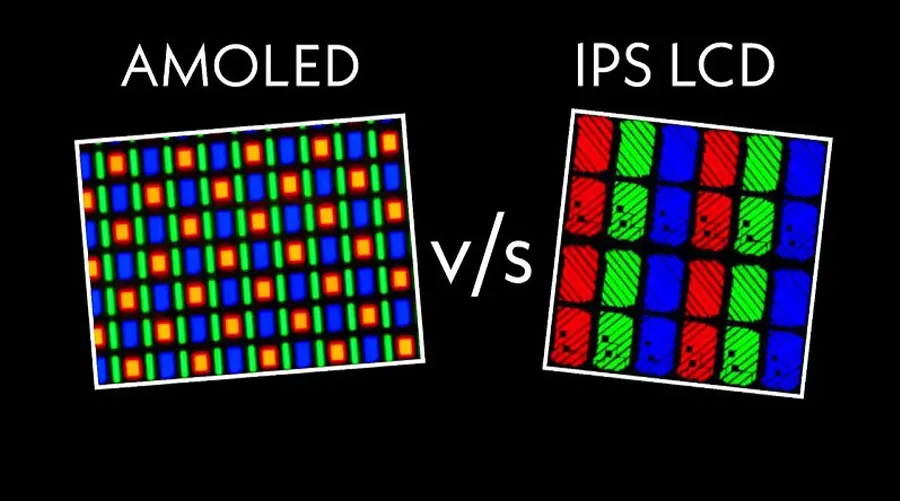

OLED vs AMOLED: How to Choose?

Technical Differences:

| Parameter | OLED | AMOLED |

|---|---|---|

| Pixel Arrangement | RGB Stripe | Pentile Diamond |

| Lifespan (50% Brightness Loss) | 30,000 Hours | 25,000 Hours |

| Cost | High (Medical/Industrial Grade) | Low (Consumer Grade) |

Recommendation: AMOLED suits smartphones; OLED is preferred for industrial/medical applications.

Foldable Phones: 200,000-Bend Durability Test

Key Technologies:

Armor Aluminum Hinge Frame: Samsung Galaxy Z Fold5 achieves 1.4mm bending radius.

CPI Film Encapsulation: Improves scratch resistance by 60%.

Selection Guide: Interfaces & Supplier Audits

Interface Protocols: SPI vs I2C vs LVDS

Recommended Solutions:

SPI Interface: Ideal for high-speed refresh (medical imaging) at 50MHz.

Dual-Mode Design: Industrial HMIs prefer SPI + LVDS (e.g., Brownopto modules).

Supplier Audit: Four Core Metrics

Certification Standards:

RoHS: Restriction of Hazardous Substances.

ISO 13485: Medical Device Quality Management System.

Production Requirements: Minimum 50K monthly capacity, delivery cycle<30 days.

Future Trends: Printed OLED & Transparent Screens

2025 Key Breakthroughs:

Printed OLED Mass Production: 30% cost reduction, 90% yield.

Transparent OLED Adoption: >45% transparency for AR windshields.

Market Forecast: Global industrial OLED market to reach $12.8B by 2027 (CAGR 18.3%).

OLED has evolved from "premium option" to "scenario necessity". Partnering with IATF 16949-certified suppliers (e.g., Brownopto) and optimizing designs for specific use cases is critical for building technological barriers.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si

Recommended products

-

2.06-inch OLED Display | 410×502 Resolution | 600 Nits | SPI Screen

The 2.06-inch AMOLED display module is designed specifically for harsh industrial environments, feat

-

3.92 INCH OLED Screen I2C Interface 1080 × 1240 Resolution

Product Specifications: BRO392001AResolution: 1080x1024Operating Voltage Range: 28VScreen Size: 3.92

-

6.01 INCH Display OLED screen | High Definition 1080x2160 | MIPI Interface

Product Specifications: BRO601001ADisplayMode: AMOLED Screen Size (inch): 6.01 Resolution: 1080x2

-

4.39 INCH OLED display module I2C Interface 568×1210 Resolution

The 4.39-inch AMOLED display module (model BR439102-A1) introduced by (Shenzhen Brownopto Technology

-

5.48 INCH AMOLED Display Module - 1080x1920 I2C, MIPI DSI, Industrial

Product Specifications: BRO548001AResolution: 1080x1920Operating Voltage Range: 2.8VScreen Size: 5.4